Metal forging has been around for a long time.

Around 6,200 years ago (4,000 B.C.), man started forging iron and bronze to produce tools and weapons. However, metal forging as we know it today is different.

The steam hammer was the first forging machine to revolutionize the metal forging process.

Since then, the process of hammering, pressing, or rolling using a variety of temperatures has helped shape all kinds of metals into applications that are used in both industrial and commercial settings.

In the following sections, we’ll discuss the seven most common forms of metal forging to give you a better idea of which process would be best suited to your custom-metal parts project.

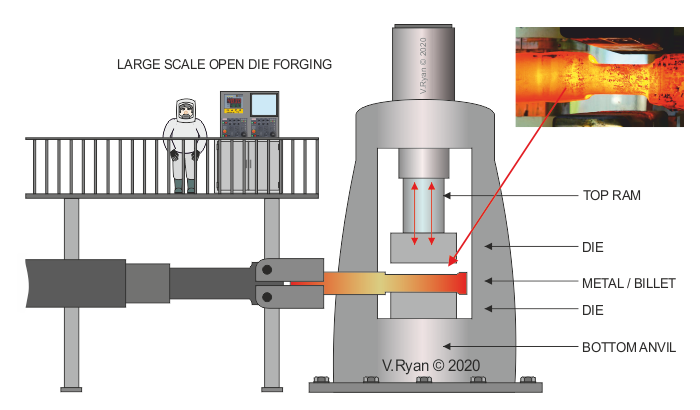

Open die forging is also called free forging or smith forging. In this method, heated metal is shaped using a top die and a bottom die.

A ram is used to push the top die down onto a heated metal billet that is inserted just above an anvil, hammer, or bolster, which presses up against the bottom die.

The general process involves the following two steps:

This process is repeated multiple times to form and change the metal in various ways.

Some of the major metallurgical changes that take place during open die forging include:

An important advantage of this open die forging is its ability to form both complex and simple shapes for a wide variety of metals and alloys, including steel, nickel, copper, and titanium, which results in a multitude of different parts and products.

Some of these parts and products can include:

While this process offers many advantages for a variety of applications, its main disadvantage is that it can not be automated—skilled workers are constantly required to maintain the continuous movement (in and out) of the workpiece between the two dies to reach the desired shape.

However, it is one of the most cost-effective forging processes available today, and it has low material waste.

Combine that with its ability to shape and form various metals and what results is a broad spectrum of products and components for commercial and industrial use.

Closed die forging, also called impression die forging, also uses pressure to compress and form billets.

However, unlike open die forging, this method utilizes an enclosed die impression (pre-formed die) to achieve desired and predetermined shapes.

No hammering or ramming is required in closed die forging as the combination of pre-shapen dies, compression pressure, and induction heating furnaces automatically melts and shapes the workpiece to specification.

The process involves three steps:

Since there is no need for billet movement in and out of the die chamber and no hammering required to forge it, the process can be fully automated, leading to a high degree of accuracy in dimensional shape and size.

Other benefits accrued from closed die forging include:

Due to its high precision shaping, closed die forging has become the ideal forging process for many small parts that require a high degree of safety.

Some of these include:

As with all forging methods, close die forging also comes with some disadvantages, namely high die production costs and high tooling costs due to the need for furnaces and machines.

Its high operating costs make it an unlikely candidate for short and smaller production projects with low volume and profit margins.

However, it is the forging method of choice for smaller components that require highly-precise shapes and designs.

These components are mostly found in the automotive, oil and gas, agriculture, forestry, and mining industries.

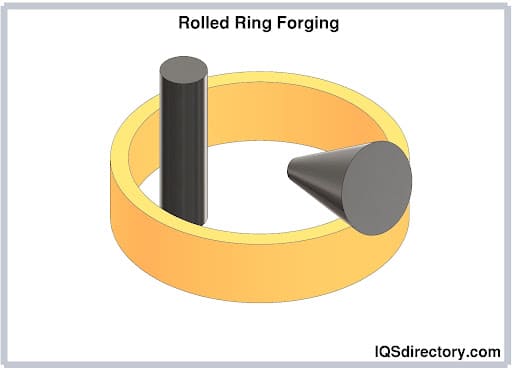

During the rolled forging process, also called seamless rolled ring forging, specially-made rolling dies are used to form a thin ring shape from a flat and thick piece of metal.

Then, a hole is punched in a flat, solid, and round metal, which creates a donut-shaped workpiece which is then pressurized to reshape it into a thinner ring-shaped structure.

The main purpose of the thin, ring-shaped design is to produce products and parts with stronger densities and better-situated grain flows, which results in improved fatigue and impact resistance.

The rolled ring process can be further explained through the following three steps:

By using this forging method, rings of almost any size and shape, as well as any width, can be formed.

Other benefits of using the rolled ring forging method include:

| High heat strength | the shape holds well in hot environments |

| Wide range of materials | any forgeable metal can be used |

| Cost-effective | less manufacturing is needed since rings closely match the structural contour of the final product shape |

Even though the above benefits may offer several advantages over other forging methods, rolled ring forging is not without its drawbacks.

The main disadvantage of rolled ring forging lies in the fact that while less manufacturing is needed to complete the shape, the equipment needed to produce forged rolled rings can be quite expensive.

Another problem with this method is that the quality of the finished product can sometimes be lowered by defects in the starting material.

However, rolled ring forging offers more solutions than problems, which is why it is often used to create parts for engines and other machinery found in both the automotive and aerospace industries.

A sample of such parts can be seen below:

Since the rolled ring forging process is extremely versatile and creates strong and lightweight rings of almost any size, businesses operating in the automotive, aerospace, and medical industries use it quite frequently to help build a variety of applications that operate in high-heat environments and under stressful situations.

The press forging method uses a press machine to shape metal. The press machine applies pressure to the metal, which causes it to deform and take on the desired shape.

Three types of press machines may be used for press forging: mechanical press, hydraulic press, and screw press.

A description of each one is given below:

| Mechanical press | uses a ram in a linear motion to force the metal stock into a die |

| Hydraulic press | uses a hydraulic cylinder in a hydraulic motion to move the ram down with sufficient force to shape the metal |

| Screw press | uses a screw mechanism (motion) to actuate the ram and apply pressure to the workpiece |

Whichever press machine is used, the method always follows the same sequential steps.

These include:

Due to the compressive stress generated by this forging method, tremendous strength and durability is achieved.

A high degree of precision finish is also actualized because of the high amount of control and accuracy of compression, which is employed during this process.

Other advantages to using press forging include:

One of the only drawbacks to this method is that a great deal of material waste is generated, especially if work material is not estimated properly before pressing begins.

Still, the press forging method is ideal for many aerospace, automotive, and medical components as press forged parts offer more strength, durability, and shape accuracy than other forging methods can provide.

Some of its more common applications include:

Its ability to create strong and durable high-quality metals in a variety of shapes and sizes has made it one of the most efficient forging methods in recent history.

It has become so popular that it is expected to become one of the most dominant forging methods of the future as many new technological advances continue to expand its capabilities and efficient output.

The upset forging method utilizes localized compressive forces to increase the thickness and diameter of workpieces.

In upset forging, constant pressure is applied to a workpiece through the use of a hammer or similar impact device.

Since hammering occurs around the circumference of the material during this process, the workpiece is deformed plastically, which results in an increase in diameter (thickness), making the metal stronger and more durable.

To make the initial workpiece thicker, the following process is followed:

While upset forging allows for thicker metal workpieces, it can also create smaller parts out of larger ones, so both long and thick, as well as short and thin pieces can be created through this single method.

The following benefits are accrued through upset forging:

As the upset forging method can produce long, thick, and durable metal parts, it is widely used in industries that require these shapes and properties, including aerospace, automotive, construction, and medical.

A list of the more popular upset forged parts being used in these industries is given below:

Even though upset forging comes with a high scrap rate, this additional wastage cost is offset by the shorter cycle times, multiple part capabilities, and improved part quality it provides.

As with many of the other forging methods previously mentioned, isothermal forging uses heat to soften the metal and reshape it via a hammer or press.

However, isothermal forging is mostly used to create small parts as its forging capabilities are much more precise than other more traditional forging methods.

The isothermal forging process is as follows:

One of the main differences between isothermal forging and other forging methods is that the temperature remains constant throughout the entire process since the dies and workpieces are simultaneously heated at the same temperature.

And this helps minimize distortions and eliminates the need for cooling the metal after each step, as is common in other cold forging methods.

Other benefits include:

Like with any other forging method, there are some disadvantages as well. The biggest one of isothermal forging is that the process is very slow, making it unsuitable for mass production.

The second drawback is that it is more useful in producing parts with simple shapes and therefore is not suitable for forging all metals.

That being said, the process can still forge steel, aluminum, brass, and copper with relative ease, making it a good choice for several applications in the automotive, aerospace, construction, oil and gas, and agriculture industries.

Flashless forging or near-net shape forging is a precise metal forging technology that uses high pressure and high temperature to form metal parts.

During flashless forging, the workpiece is heated in an oven instead of a flash furnace which helps speed up the forging process and keeps costs to a minimum.

The exact steps of this method are given below:

The process is faster and more efficient than most forging methods and offers a near-net shape and high-quality finish with exceptional dimensional accuracy.

A summary of the advantages of flashless forging is this:

Despite the many advantages of flashless forging, there are a few key disadvantages to this method.

The first one is that it is often very wasteful. The speed at which the metal is heated can result in excess material being thrown away.

Secondly, the high temperature at which the metal is heated can potentially cause damage to the workpiece.

Lastly, flashless forging is not an ideal choice for high-volume projects because flash-forged parts are difficult to modify and alter, so if any changes are needed, the process comes to a halt and may have to be restarted.

However, industries in need of small and intricate components often use this forging method to create them.

Some of the most popular forged parts utilized by the aerospace, automotive, and medical industries include:

In the future, flashless forging is expected to become one of the most highly used forging methods to create small and precise components.

That’s because it results in a higher quality product with little to no defects, lower manufacturing costs, and manufacturing times than most of the other traditional forging methods.

The metal forging methods listed above provide many benefits for metal-parts manufacturing.

The overall process allows manufacturers to create parts with high strength and durability, as well as with complex features and intricate designs.

However, as there are many metal forging methods to choose from, it would be wise to consult with a metal parts manufacturer who has a good working knowledge of each one.

In that way, you won’t have to waste time and money on forged parts that don’t meet the requirements for your specific applications.

Contact BUNTY LLC Today

For further information about metal forging methods, contact us directly via the convenient website form or request a quote here. We welcome your inquiries.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote