Sand casting plays a huge role in domestic manufacturing in the US, remaining relevant thanks to its versatility and cost-effectiveness.

It involves pouring molten metal into specially bonded sand parts for different uses, and is one of the go-to methods for creating complex metal parts.

However, finding a reliable sand casting manufacturer that can consistently deliver quality and precision can be a challenge.

That is why we have put together a list of leading companies that provide sand casting services to meet the demanding needs of the US market.

Let’s start with our own company, Bunty LLC, which is a top choice for high-quality sand casting services for businesses across the US and worldwide.

Founded in 2000, Bunty brings over two decades of expertise serving the automotive, aerospace, energy, medical, and other industries.

Bunty is headquartered in Greenville, South Carolina, from where we deliver global solutions supported by domestic and international manufacturing, warehousing, and inspection facilities.

This helps us ensure reliable, fast, and cost-effective production.

Source: Bunty LLC

We are AS9100D certified for the aerospace quality standard, ISO 9001:2015-accredited, as well as recognized by CVMSDC as a diverse supplier.

Bunty LLC specializes in sand casting to produce both simple and complex metal parts with precise tolerances and customized surface finishes.

Our expertise spans a wide range of industries, delivering components such as gearboxes, pump bodies, crankshafts, impellers, and more.

We also supply high-quality castings for the automotive sector, including engine blocks, transmission cases, and cylinder heads.

With advanced facilities and a commitment to innovation, we provide full project support: from consultation and design refinement to prototyping and fully machined castings.

In addition, Bunty boasts a whole range of capabilities and value-added services, from forging, machining, and metal surface treatments to quality inspections and prototyping.

Overall, Bunty is capable of adapting to unique project requirements and can confidently deliver complex, custom jobs with consistent precision and quality.

This makes us a reliable partner for even the most demanding manufacturing needs.

Founded in 1966 and located in Milwaukee, Wisconsin, Badger Alloys is another good option for sand casting solutions in the US.

It’s a full-service provider for sand casting, certified to ISO 9001:20015 and Pressure Equipment Directive, commonly known as PED, for the European Market.

With their certified welders and state-of-the-art equipment, they offer on-site sand casting, pattern making, machining, and engineering services.

This ensures they have control over the quality, reduces the time of production, and minimizes errors.

Source: Badger Alloys

Badger Alloys pride themselves on using an efficient airset, no-bake molding process.

This results in high-quality castings with closer dimensional tolerances and a seamless finish.

This foundry also has a reclamation unit where they clean and recycle sands, making their processes more environmentally friendly.

Badger Alloys serves a wide range of industries, including industrial valves and products, defense, water treatment, chemical, pharmaceutical, oil and gas, and food and beverage.

With decades of expertise and a commitment to quality and sustainability, Badger Alloys stands out as a trusted partner for diverse sand casting needs.

Le Sueur Incorporated, headquartered in Le Sueur, Minnesota, is a supplier of aluminum castings and plastic injection molding components.

Founded in 1946, they specialize in casting, molding, and precision machining manufacturing processes.

They also offer their customers the option of design consultations in order to help them choose the right manufacturing method.

The company has several certifications that demonstrate it’s committed to quality and compliance, particularly for sensitive defense applications.

These include ISO 9001:2015, ITAR (International Traffic in Arms Regulations, and UL (Underwriters Laboratories) certifications.

Le Sueur Incorporated specializes in green sand casting, which uses a mixture of clay, sand, and water.

Source: Le Seur Incorporated

This process is particularly effective for producing parts that are complex dimensionally and pressure-tight.

They also have a dedicated sand laboratory to monitor moisture content and compactability, ensuring consistent, high-quality castings.

Their foundry has three automatic casting lines that include inexpensive matchplate tooling and quick set-ups.

This results in an economical casting solution for lower volume production needs.

They also have two cope and drag casting lines for aluminum green sand molding.

Apart from sand casting, they offer comprehensive in-house services that include assembly of parts, machining, heat treating, and core making.

Le Sueur is a trusted partner in industries like defense, agriculture, transportation, and medical.

LeClaire Manufacturing is a family-owned foundry located in Bettendorf, Iowa, and has been in business since 1966.

They offer casting, engineering, and design services as well as CNC machining, supported by their full-service tooling shop.

This company is ISO 9001:2015 and ISO 14001:2015, which testifies to their commitment to quality management and environmental responsibility.

Source: LeClaire Manufacturing

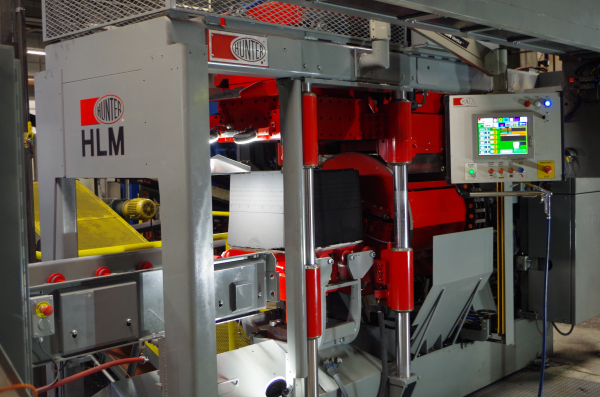

LeClaire’s sand castings are made using fully automated green sand molding machines. This, alongside their robotic ladling system, allows them to create consistent, precise, and repeatable results.

On top of that, just like Bunty, they offer in-house tooling and rapid prototyping services.

This enables them to create and test designs, which makes their production fast and time-efficient.

LeClaire Manufacturing primarily serves the automotive, marine, railroad, and defense industries.

So, if you’re looking for a foundry that combines decades of experience with advanced automation and in-house capabilities, LeClaire is a choice worth considering.

Wabash Castings is a foundry founded in 1978 and based in Wabash, Indiana.

They are ISO 14001:2015 and IATF 16949:2016 certified, and are a a Thomas Verified Supplier.

These certifications are confirmation of their commitment to environmental responsibility, quality management, and meeting rigorous automotive industry standards.

Like many others on our list, they use green sand casting processes, but also utilize a number of procedures to maintain efficiency and support the manufacturing of products.

This includes prototyping, design support, mold flow analysis, forecasting, project management, and error proofing.

Source: Wabash Castings

On top of that, they pride themselves on investing extensively in new technologies and equipment.

Wabash uses technologies like 3D printing and scanning, robotics, and X-ray to produce high-quality parts efficiently and consistently.

They primarily serve industries that need durable and lightweight aluminum components, such as the automotive and industrial machinery.

Overall, Wabash Castings combines advanced technology, strict quality standards, and extensive industry experience to deliver high-quality aluminum components efficiently and reliably.

Contact BUNTY Today

For more information about sand casting and our other capabilities, contact us through our website form or request a quote here. We welcome your inquiries.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote