In recent years, shifting global trade dynamics and outdated tariff regulations have significantly impacted the metal manufacturing sector in the United States.

For many U.S.-based manufacturers, particularly those serving industries needing custom metal parts, navigating international competition and fluctuating import prices has been a challenge.

However, new tariff policies are beginning to reshape the landscape, creating fresh opportunities for American manufacturers.

Today, we’ll break down how this changing tariff environment is fueling demand for U.S.-made metal parts, improving price competitiveness, reducing supply chain risk, and inspiring long-term growth in domestic manufacturing.

As tariffs raise the cost of foreign metals, companies across industries are seeking more cost-effective alternatives.

One clear solution is sourcing from U.S.-based metal manufacturers.

This shift is creating new opportunities for domestic suppliers who can deliver consistent quality without the added burden of international trade fees.

By working with U.S. manufacturers like Bunty LLC, businesses can avoid tariff-related price hikes and maintain high standards for quality, performance, and delivery.

Source: Bunty LLC

Bunty’s U.S.-based operations are built to meet this growing demand with efficient production, expert engineering, and reliable turnaround times.

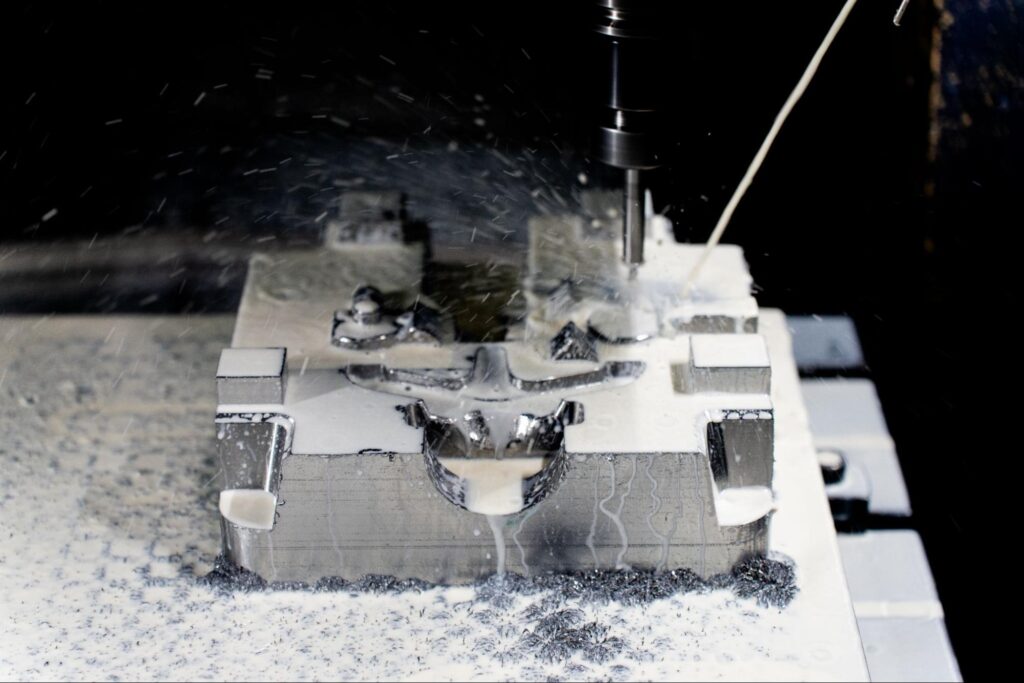

With advanced manufacturing capabilities, deep expertise in precision metal components, and state-of-the-art facilities, we provide a dependable alternative to increasingly expensive and unpredictable imports.

Source: Bunty LLC

But the benefits of sourcing domestically go beyond avoiding tariffs.

Here are additional ways U.S. manufacturers offer strategic advantages in today’s trade environment:

| Greater supply chain control | Domestic sourcing reduces exposure to global disruptions and delays. |

| Reliable delivery | Shorter transit distances improve turnaround times and reduce late shipments. |

| Responsive service | Domestic suppliers can quickly adapt to changes in production needs. |

| Stronger supplier relationships | Closer geographic proximity fosters better communication and collaboration. |

While the new tariffs have introduced pricing volatility for imported materials, they’ve also made domestic sourcing a more appealing long-term strategy.

U.S. manufacturers are stepping up to fill that gap, offering businesses greater stability, fewer risks, and reliable access to high-quality parts.

New tariff policies have increased the cost of imported metals by as much as 25%, depending on the material and country of origin.

This cost increase has created a valuable opportunity for U.S. metal manufacturers.

By operating domestically, manufacturers can sidestep costly import duties and international freight expenses.

This allows them to offer high-quality metal components at more stable and often lower prices than overseas suppliers.

Without the financial burden of tariffs or long-distance logistics, domestic manufacturers can maintain strict quality controls while delivering competitively priced components.

This is especially appealing to businesses that previously relied on foreign sources for products like custom steel forgings.

Below is a summary of the key advantages of improved price competitiveness for domestic manufacturers brought about by the new tariffs:

A recent White House fact sheet notes that demand for U.S.-made steel and aluminum is rising after years of decline, driven in part by businesses seeking to cut costs and reduce sourcing complexity.

Ultimately, domestic metal producers are becoming more appealing to cost-conscious industries that need both performance and price stability, while avoiding the risks tied to foreign sourcing.

Relying heavily on foreign suppliers can expose companies to significant risks.

Currency fluctuations, trade wars, export bans, and abrupt policy changes in other countries, as well as in the U.S, are just some of the risks that U.S. businesses currently face.

Such disruptions can quickly affect pricing, availability, and delivery schedules.

Domestic sourcing offers a more predictable alternative.

U.S.-based manufacturers are gaining traction with businesses that want greater control over their supply chains and fewer surprises from global markets.

For example, during the COVID-19 pandemic, many manufacturers dependent on imports faced long delays and shortages.

In contrast, those with domestic supply chains were better positioned to maintain continuity.

Today, with ongoing tariff tensions, especially with countries like China, the advantages of local sourcing remain clear.

Businesses that source their metal locally are not facing such unpredictable disruptions as those who choose to rely heavily on international companies to supply them with metals for their components.

Here are some of the strategic advantages of reducing global dependence on metal parts:

This move toward domestic sourcing is becoming a long-term strategy for businesses aiming to cut down on costs, as well as improve operational planning.

As more companies recognize the value of stable, local supply chains, U.S. manufacturers will continue to emerge as the preferred partners for metal components.

U.S. metal manufacturers that consistently deliver on quality, responsiveness, and reliability are gaining long-term trust from businesses navigating today’s uncertain global supply climate.

As more companies seek dependable partners for custom metal parts, domestic manufacturers stand out not just for their products, but for their ability to form resilient, service-driven relationships.

That loyalty extends beyond the supplier-customer dynamic to support the clients’ ability to deliver reliably to their own customers, reinforcing brand trust at every level of the supply chain.

Operating within the U.S. gives domestic manufacturers a clear edge:

These advantages make a significant difference for businesses that rely on just-in-time manufacturing or need rapid adjustments to production runs.

For example, manufacturers in the agricultural equipment industry often face seasonal production spikes that require urgent component deliveries.

U.S.-based suppliers like Bunty can respond quickly to these needs, while an overseas supplier would struggle to do so due to long transit times, customs delays, and time zone gaps.

Here are some key ways domestic manufacturers can gain customer loyalty and help their clients do the same:

According to a 2023 survey by ThomasNet, 83% of U.S. companies said they preferred to work with domestic suppliers specifically because of stronger communication and delivery reliability.

These preferences often evolve into repeat business and multi-year contracts, building loyalty on both sides.

Once trust is earned, domestic manufacturers are in a strong position to lead their customers into the future with new technologies and smarter solutions.

The shifting landscape created by new tariff policies isn’t just driving demand toward local sourcing, but is also motivating U.S. metal manufacturers to innovate.

To meet rising expectations around speed, quality, and cost-efficiency, U.S. metal manufacturers are investing in advanced technologies that streamline operations and increase competitiveness, at home and globally.

This includes automation, robotics, advanced quality control, and data-driven production methods.

These upgrades help manufacturers scale more efficiently, reduce waste, and maintain high precision without driving up costs.

Bunty LLC is among those leading this charge, continuously reinvesting in state-of-the-art equipment and process optimization to meet growing demand and adapt to changing customer needs.

Source: Bunty LLC

Here’s how these innovations are helping domestic manufacturers stay ahead:

On top of that, innovation reduces dependence on tariffs by making domestic production cost-effective on its own.

In fact, 54% of manufacturers increased their investment in new technology in 2024 in response to changing trade dynamics and supply chain pressures.

The result is a more agile, forward-looking manufacturing sector that isn’t just reacting to policy changes but using them as a launchpad for long-term progress.

Rather than relying solely on tariff protections, U.S. metal manufacturers are building a self-sustaining edge through innovation that delivers lasting value to their customers and enhances their relevance on the global stage.

Tariffs may have reshaped global trade, but for U.S. metal manufacturers and their customers, they’ve opened the door to smarter sourcing, faster turnaround, and stronger partnerships.

By making imported metals more expensive, these policies have increased demand for domestically produced parts, strengthened pricing leverage for local manufacturers, and reduced reliance on unpredictable global markets.

If you’re rethinking how and where you source custom metal parts, now’s the time to choose a partner that offers more than just products—one that delivers reliability, responsiveness, and real peace of mind.

At Bunty, we deliver it all.

Contact BUNTY Today

Contact us today to learn how our domestic operations can support your success with precision, efficiency, and confidence. We welcome your inquiries.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote