The performance, design, and quality of industrial parts directly impact your company’s productivity and success.

When components are made from subpar materials or outdated manufacturing processes, they can compromise your entire operation.

To get the best return on your parts investment, you need components made with advanced manufacturing methods, like Computer Numerical Control (CNC) machining.

While machining as an occupation has existed for over 150 years, CNC machining has revolutionized it.

This cutting-edge process uses computer-guided tools to produce highly accurate parts from metals, plastics, and even wood.

At Bunty LLC, we specialize in CNC machining services that deliver unmatched precision, repeatability, and quality.

Below, you’ll find the types of CNC machining we offer—and why companies across industries trust us to get the job done right.

At Bunty LLC, we offer several different types of CNC machining services.

Whether you need high-volume production, intricate designs, or tight tolerances, our capabilities can support your project from start to finish.

Milling as a fabrication process dates back to the 19th century, originally used to shape wood.

As technology progressed, milling evolved into a method for cutting and forming metal parts with greater precision.

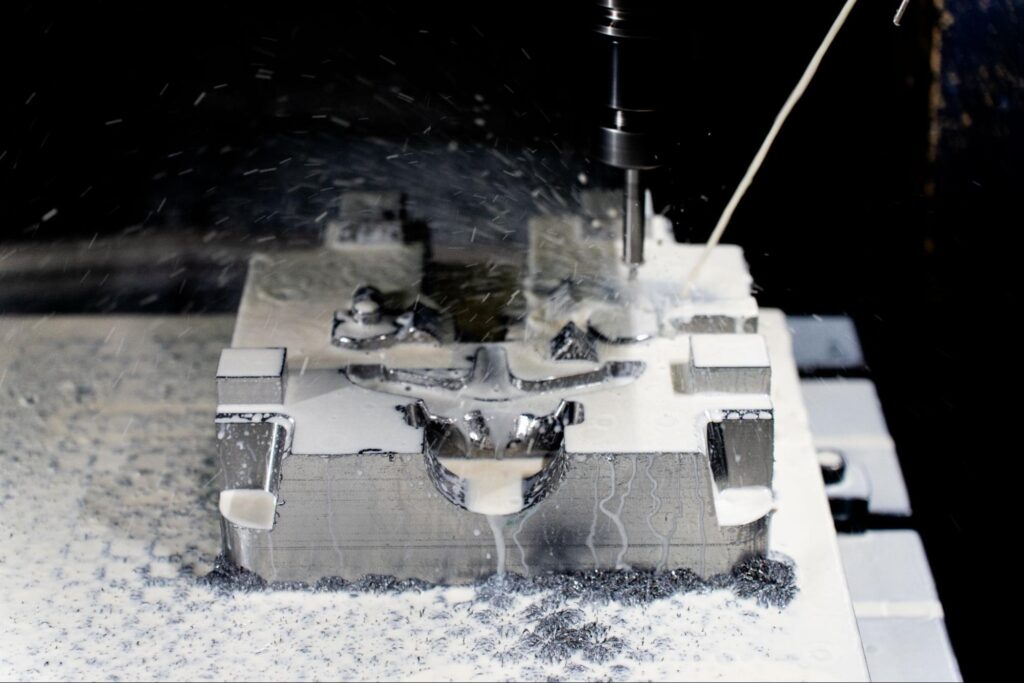

Today, CNC milling uses computer-controlled systems to produce highly detailed, complex components from a wide range of materials.

Source: Bunty LLC

The process relies on a computerized processing unit that directs rotary cutting tools along programmed coordinates within a numerical grid system.

CNC milling machines typically operate on either vertical or horizontal axes—vertical being the most common.

Source: Bunty LLC

This automated precision allows Bunty LLC to manufacture large volumes of consistent, high-quality parts with tight tolerances.

We offer a range of CNC milling capabilities:

You can also choose parts made with CNC turning.

CNC turning is used to create cylindrical or rounded parts by rotating the workpiece while a stationary cutting tool removes material.

The result is smooth finishes and precise dimensions, especially for symmetrical components.

There are two main categories of CNC turning: external and internal.

External CNC turning focuses on shaping the outside of a cylindrical part, with the following techniques:

Internal CNC turning targets the inside of a part.

Drilling is used to create holes by removing material from the interior.

If the hole needs to be more precise, reaming is performed to slightly enlarge and smooth the initial hole to exact dimensions.

Boring goes a step further by using a rotary blade to expand and finish internal cylindrical cavities.

Lastly, tapping cuts threads inside a hole, allowing it to receive a screw or bolt.

Bunty LLC also offers 5-axis CNC machining.

This fabrication process uses a single setup to create intricate parts with complex geometries.

The cutting tool moves along three linear axes (X, Y, and Z) and two additional rotational axes (A and B), enabling access to virtually any surface of a part.

Source: American Machinist

Key advantages of 5-axis CNC machining include:

It’s especially valuable in industries like aerospace, medical, and automotive where precision and efficiency are critical.

We also offer CNC laser cutting, which uses a high-powered, computer-controlled laser beam to cut, engrave, or mark a wide variety of materials with extreme accuracy.

Source: Bunty LLC

Carbon dioxide lasers, laser microjets, and fiber lasers are among the different types of lasers used in this type of CNC machining.

The three main laser cutting system configurations are:

Laser cutting is ideal for producing detailed, complex shapes with minimal waste and rapid turnaround.

It offers consistent results, high efficiency, and broad material compatibility.

At Bunty LLC, we partner with a wide range of industries to deliver CNC-machined parts that fuel innovation, enhance performance, and keep operations running smoothly.

But why do so many industries rely on CNC machining?

Because it offers unbeatable advantages, such as:

So, what are some of the applications that we serve at Bunty LLC?

Our CNC machining services cater to a wide variety of clients, including those in the aerospace and defense industry.

Our company specializes in creating parts for satellites, aircraft, and defense systems.

Likewise, clients in the automotive industry rely on Bunty LLC for customized parts.

You will find our parts in chassis, transmissions and engines.

We also support the medical and healthcare industry with intricate components like surgical tools, implants, and parts for diagnostic equipment.

Here, precision CNC machining delivers is unbeatable.

Meanwhile, in the energy, oil, and gas sector, durability takes center stage.

We create robust machined parts for turbines, drilling rigs, and renewable energy systems built to perform in extreme conditions.

And let’s not forget industrial and heavy equipment, a sector we’ve supported since our founding.

Our clients trust us to produce parts for automation systems, manufacturing machinery, and advanced robotics.

No matter the industry, our goal remains the same: to deliver CNC-machined components that meet your specs, exceed your expectations, and drive your success forward.

When it comes to CNC machining services, experience, precision, and speed matter—and Bunty LLC delivers on all three.

With decades of industry experience and cutting-edge equipment housed in modern, high-efficiency facilities, we’re a trusted leader in CNC machining for businesses across the globe.

Thanks to our headquarters in Greenville, South Carolina, and additional locations throughout Asia, we offer fast turnaround times without ever compromising on quality.

Source: Bunty LLC

Whether your project requires complex geometries, tight tolerances, or high-volume production, we deliver cost-effective, precision-driven solutions—on time and to the highest standards.

Our clients choose Bunty not just for our technology and expertise, but because we’re committed to doing things right.

From the first prototype to the final part, our team ensures quality at every step.

Source: Bunty LLC

We also hold AS9100D, ISO 9001:2015, and CVMSDC certifications, reinforcing our reputation for excellence in manufacturing.

Looking for a CNC machining partner?

Here’s what to consider:

Bunty LLC checks every box.

Contact BUNTY Today

Contact us today to discuss your custom machining needs and get a quote!

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote