Superalloys (a.k.a. high-performance alloys) are typically composed of nickel, iron-nickel, and cobalt alloys.

An alloy is a metal that is made by combining two or more other metallic elements (i.e. nickel, iron, zinc, tin) to strengthen the microstructure and increase its corrosion resistance.

Since these metals can retain their strength, stiffness, and dimensions under high temperatures and have high corrosion and oxidation-resistant properties, they are widely used in the manufacturing of materials that operate in extreme environments.

In the following sections, we will discuss superalloys in further detail including their properties, benefits, and applications in various industrial settings.

Superalloys can be classified according to their predominant elements: nickel, cobalt, or iron.

However, since superalloys consist of a matrix of metals that produce their outstanding strength and corrosion-resistant properties, they often include other refractory metals such as chromium and titanium which have high melting points (1850 °C to 2200 °C).

All combinations of superalloys exhibit high melting points and have several other key characteristics that set them apart from other common manufacturing alloys.

These include:

Some prime examples of superalloys that are used in high-temperature and highly-corrosive industrial settings include:

While superalloys can be traced back to 1907, most of the superalloys seen today are a result of the hot working and heat-treating processes that have developed in the last 50 years or so.

These technological breakthroughs in superalloy processing have made these high-performance metals very popular among manufacturers of metal parts in the air, space, and ocean industries as they have solved many of the problems relating to strength, durability, and oxidation facing machines and systems operating in these extreme environments.

As was mentioned earlier, superalloys can either be nickel-based, iron-based, or cobalt-based.

While the main components of each of these super alloy families will be the primary metal element it is named after, each one contains other refractory and non-refractory elements to help in the casting and powder metallurgy process.

Since superalloys can withstand a tremendous amount of heat, they are extremely ductile making it difficult to use hot and cold processing methods for chemical alteration without adding other elements to their composition.

The following is a breakdown of the three main superalloy families including their composition and properties.

These superalloys are an excellent choice for high-temperature applications that require strong resistance to fatigue and creep as well as protection against severe oxidation and corrosion.

Aside from nickel, this class of high–performance alloys contains solutes such as aluminum and titanium, as well as other chemical elements like iron, tungsten, chromium, cobalt, and molybdenum.

This composition gives nickel-based superalloys the following properties:

Due to their chemical and machinability properties, nickel-based superalloys are used in a wide range of applications across the aerospace, marine, chemical, and nuclear industries.

Iron-based high-performance alloys are known for both their high temperature and room temperature strength and also for their resistance to corrosion, oxidation, creep, and wear and tear.

Superalloys which are composed mainly of iron typically come with a matrix of other alloying elements. The most common of which are aluminum, boron, carbon, cobalt, chromium, titanium, nickel, molybdenum, niobium, silicon, and tungsten.

When more carbon is added to an iron-based superalloy, its resistance to wear and tear increases.

Its unique composition of alloying elements gives iron superalloys the following properties:

Out of the three main categories of superalloys, the iron-based family is the least expensive to use for manufacturing purposes.

These classes of superalloys have good mechanical properties and as with the other families of superalloys, are corrosion-resistant and have a tough exterior making them very durable.

A unique feature of cobalt-based alloys is their high resistance to sulfides (binary compounds of sulfur), which prevents sulfidation from occurring.

Cobalt alloys primarily consist of cobalt and chromium and usually contain tungsten, molybdenum, and nickel.

When nickel is added to a cobalt-based alloy it becomes more heat-resistant.

The combination of cobalt, chromium, tungsten, molybdenum, and nickel provide cobalt alloys with the following properties:

Due to its high melting point, cobalt superalloys are often used in applications that work in very high temperatures such as in gas turbine engines.

Of the three families of superalloys listed above the nickel-based ones have the widest range of applications, the iron-based alloys are the least expensive to use, and the cobalt-based superalloys are the prime choice when superheat resistance is needed.

There are two general methods for processing superalloys: investment casting and powder metallurgy.

These two procedures are often used in conjunction with five other processing methods: vacuum induction, secondary melting, conversion, directional solidification, and single-crystal growth.

First, we will define the two main processing methods (casting and powder) before describing the other steps that are often added before or after casting or powder metallurgy.

This casting method is also known as lost-wax casting as it uses wax model replicas to create complex shapes and dimensions out of melt (molten metal).

There are eight main steps in investment casting, which can be seen below:

Investment casting is used for wearable parts that require dimensional accuracy, smooth surfaces, and low tooling costs.

In powder metallurgy, metal powder mixtures are used to form superalloys needed for critical fatigue applications.

Sintering is often used during this process to convert metal powders into mechanical parts.

There are three main steps in powder metallurgy.

They are as follows:

Modern technology has also made it possible to use 3D printing to create parts from superalloy powders.

Now, we will discuss the five additional steps used in superalloy processing.

In this step, raw materials are placed into a vacuum where they are melted with electrical currents.

Its main function is to help improve chemical composition, especially before using the investment casting process.

This additional melting process is often added to help reduce fatigue problems that are associated with vacuum induction by increasing the chemical homogeneity of the melted material.

Ingot conversion uses a thermal-mechanical deformation process to enhance and control the microstructure of materials produced during secondary melting.

During this process, superalloys are placed on a low-temperature surface (gradient) and are allowed to cool and nucleate (cluster) to strengthen their creep resistance properties.

During this slow process, superalloy components are grown and solidified from a single seed crystal to remove any grain boundaries, which helps increase their creep and thermal fatigue resistance.

To get a better understanding of how all these steps work together during investment casting and powder metallurgy, please refer to the following diagram: Superalloy Processing Flow Diagram.

High-performance superalloys are considered to be the most successful alloy system of all time due to their special attributes which bring a host of benefits to many of the applications and technologies we use today.

Many of their general properties have already been discussed in earlier sections, but the following lists offer more insight into their properties, attributes, and benefits.

First, let’s take a look at why they are commonly used in a variety of modern-day applications:

Superalloys can exhibit the above properties due to a host of attributes, the foremost of which are listed below:

Now, let’s take a look at some of the distinct benefits provided by each of the three classes of superalloys (nickel, iron, and cobalt).

Nickel-Based Alloys: provides versatility, high toughness, increased corrosion & oxidation resistance, strength in high & low temperatures, and magnetic & electronic properties.

Iron-Based Alloys: provides more strength, more versatility, and more corrosion resistance than pure metals.

Cobalt-Based Alloys: provides water resistance, extreme-heat resistance, sulfide resistance, and high strength & durability under extreme conditions.

Along with their wide range of beneficial properties and attributes, comes a wide range of manufacturing possibilities.

The next section will cover the applications of superalloys across various industries.

Superalloys are used in many applications across a host of industries.

Industries such as aircraft & aerospace, chemical, nuclear, metal, medical, and automotive all use superalloys to form pertinent components and parts for their most important applications.

The following is a breakdown of industry-specific applications and components that are comprised of superalloys:

| Aerospace & Aircraft | Rocket-Engine Parts Aerodynamically Heated Skins Aircraft Gas Turbine Components (disks, bolts, shafts, cases, blades, vanes, combustors, and afterburners) |

| Nuclear (Components) | Valve Stems Ducting Springs Control Rod Drive Mechanisms & Components |

| Chemical (Products) | Bolts Valves Springs Ducting Reaction Vessels |

| Automotive (Components) | Turbine-Driven Chargers Exhaust Valves |

| Medical (Components) | Dentistry Components Prostates |

| Power Plants (Steam Turbine Components) | Bolts and Blades |

| Metal Processing (Products) | Hot Forming Tools & Dies |

| Heat Treating (Equipment) | Trays Fixtures Conveyor Belt Furnaces |

Aside from the heavy-duty applications listed above, superalloys are also used in many of the common and health-related technologies that we use and benefit from today such as airport hot spots and biomedical implants.

A breakdown of the specific applications for each class of superalloys is given below:

Nickel-Based Alloy Applications: aerospace components, power generation parts, and automotive applications requiring high heat resistance.

Iron-Based Alloy Applications: medical components, chemical synthesis applications, construction applications & tools, and tooling products.

Cobalt-Based Alloy Applications: gas turbine components, space power systems, chemical plant components, nuclear power plant components, and orthopedic implants.

As of today, superalloys are the most widely used in aerospace and defense applications and this is expected to continue and rise at a seven percent growth rate until 2026.

This section will cover some important tips about recycling superalloys.

Superalloy recycling is important because many of the elements that go into creating high-performance alloys are becoming more scarce as time goes on.

Take the current situation facing the aviation industry today.

As aircraft engineers continue to improve and create new high-performing aircrafts and engines the demand for superalloys to manufacture applications and parts that can operate in extreme temperatures increases.

When high-performing technologies are continually produced and the primary materials that support them continue to decrease, the result is a non-sustainable growth rate in the future advancement of technological breakthroughs.

This is why superalloy recycling is not just a recommendation for the health of future industrial growth but a necessity.

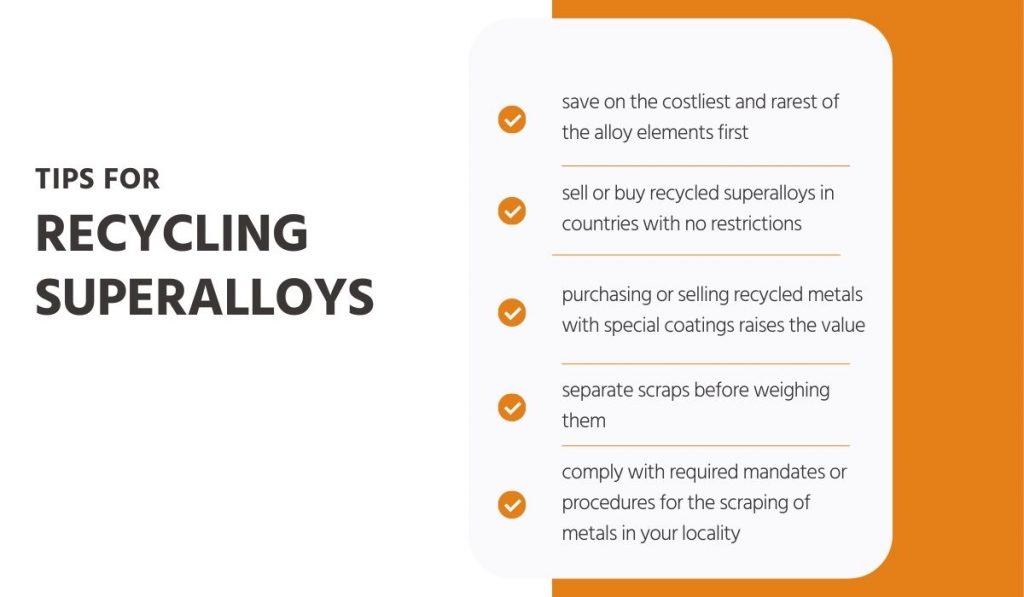

Below are five tips for recycling superalloys that will give businesses operating in fast-paced industries a competitive advantage in securing energy-critical elements (ECEs) that are essential for energy production, storage, transmission, and supporting new technologies operating in extreme conditions and environments.

The newest generation of superalloys contains a good amount of rare earth elements such as Ruthenium and Rhenium and since they are so rare they are also very costly – $1.5 per gram and $10 per gram.

The limited supply and high cost of rare earth metals make them more valuable than the total sum of the other alloys they are combined with.

Simply put, it is important to save on the costliest and rarest of the alloy elements first and foremost before striving to rescue and reuse the rest of the superalloy content.

The trading of scrap metals in different countries may or may not come with sanctions, embargoes, and other restrictions.

The U.S., for example, has many trade policies in place such as ITAR that impose embargoes, restrictions, and even sanctions on many countries to regulate the sale, manufacture, and distribution of metals.

However, some countries like Canada do not impose any restrictions or require registrations and applications for the import or export of scrap metal making it an ideal choice for the purchase and selling of recycled superalloys.

If you are going to buy or sell recycled superalloys, then you should know that the addition of superalloy coatings offers more value as they allow them to operate at even higher temperatures than they would normally be able to.

Therefore, don’t be surprised to find a higher price tag if you are purchasing recycled metals with special coatings, and don’t forget to raise your price tag when selling yours.

If you want to get the best price for your superalloy scrap then be sure to separate them before you weigh them.

This process can be done through external services or you can do it yourself.

If you would like to learn more about how to separate and recover metal alloys from superalloys, visit: Separation and Recovery of Metal Alloys from Superalloy scrap

Any time you are going to dispose of any material, including scrap superalloy metals, for sale or distribution you will need to stay compliant with local regulations governing their disposal.

Although it is not possible to give you specific instructions on how to stay compliant or obtain the required certifications regarding the disposal and recycling of scrap metal in your area, we can direct you to some general guidelines that will complement any required mandates or procedures for the scraping of metals in your locality.

To learn more about how to recycle scrap metal, read: How to Recycle Scrap Metal.

Recycling superalloys can be a very lucrative business in and of itself, but it has the added benefit of saving precious elements that are fundamental to the future of high-tech applications and the benefits they bring to daily life.

Anytime you have a chance to save your superalloy material or purchase recycled alloys, you should take advantage of it for the sake of your business and humanity at large.

Superalloys are prized by many industries that operate under harsh environments and extreme temperatures due to their mechanical strength, solid surface stability, thermal creep, oxidation and corrosion resistance, and ability to operate effectively at high melting points.

They are especially useful in today’s high-tech world where higher application performance usually equates to higher temperatures and tougher environments.

While superalloy applications are predominantly associated with the aerospace, chemical, petrochemical, power, and marine industries, their ability to work cohesively with newer manufacturing technologies such as additive manufacturing and 3D printing has made them even more popular and widely used than ever before.

For further information about our services and work with superalloys, contact us via the convenient website form or submit a request for quote directly. We welcome your inquiries.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote