Metal casting has long been used in many industries to produce metal components with complex shapes and designs that are often difficult, if not impossible, to create with other manufacturing techniques.

In the following sections, we shall cover six major industries that use metal castings regularly for running many of their systems and producing components for their products, while going into further detail about the specifics of why they need them and how they use them.

By the end of this article, it should be clear why this powerful metal manufacturing process can so efficiently meet the diverse needs and demands of these industries.

The automotive industry relies heavily on metal casting processes to manufacture a wide range of components that require high strength and durability to meet the demands of automotive applications.

In 2020, the automotive casting market crossed over $107.2 billion and is projected to grow over 5 percent from 2021 to 2027.

The reasons for such heavy use within this industry are many, but the most important ones include the efficiency of the process itself, as well as the added features and properties it enhances for automotive parts.

For example, the process can produce the following results:

The above advantages give rise to a host of applications within the automotive industry which would otherwise be much more inefficient and costly.

Some of the most common applications of metal castings within this industry include:

As can be seen from the above applications, metal casting is used quite effectively for producing various automotive components that have different functions, materials, and shapes.

The many benefits the process offers for the production of automotive components (e.g. weight reduction, improved performance, enhanced quality, and cost-effectiveness), make the casting process a necessary manufacturing method for automotive parts.

The construction industry is one of the largest consumers of metals in the world, accounting for 50 percent of the total world steel consumption.

Therefore, it’s not surprising that the industry would have such a strong interest in the production of metal-cast parts for its applications.

Aside from needing metal castings for its core products, there are many other reasons the steel industry prefers metal castings for manufacturing its metal components over other methods.

The reasons are the following:

Aside from the examples of the applications mentioned above, the construction industry also relies heavily on metal castings to produce manhole covers and sewer pipes, which are often made from cast iron because of their sturdiness, durability, and resistance to corrosion and abrasion.

Simply put, metal castings play a vital role in the construction industry:

They offer many advantages like large-scale component production, improved structural performance and appearance, and safety enhancement of construction equipment, which many other manufacturing methods are not able to match.

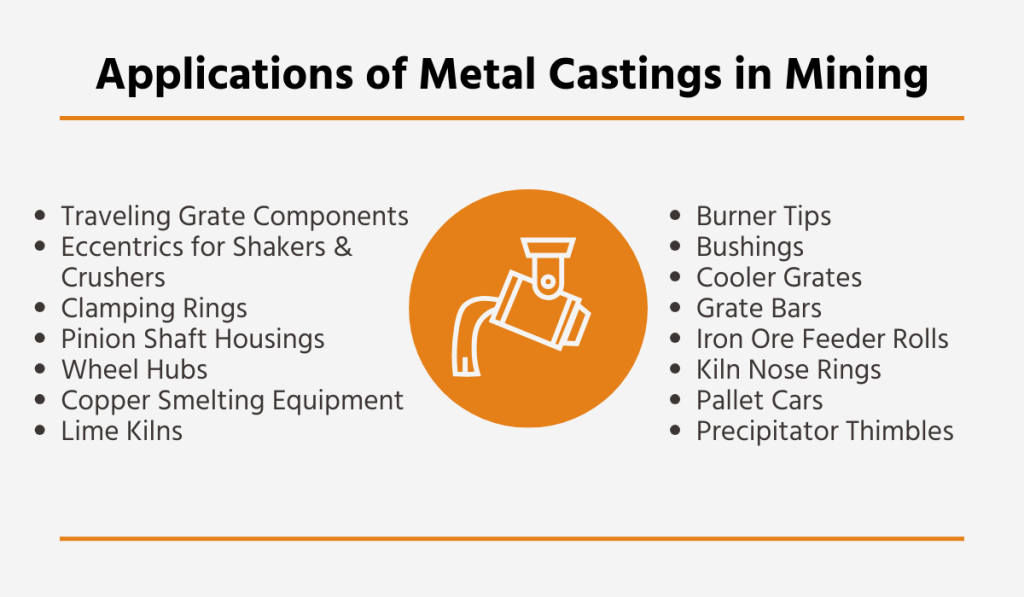

The mining industry utilizes the metal casting process for manufacturing various types of mining equipment and machinery.

The strength, durability, and resistance to harsh conditions, as well as the heavy loads that metal castings provide, are ideal for the conditions often found in this industry.

Some of the major benefits metal castings offer the mining industry are:

The most prominent applications of metal castings in the industry include:

Given the breadth of applications of metal castings, it is clear what importance they have within the industry.

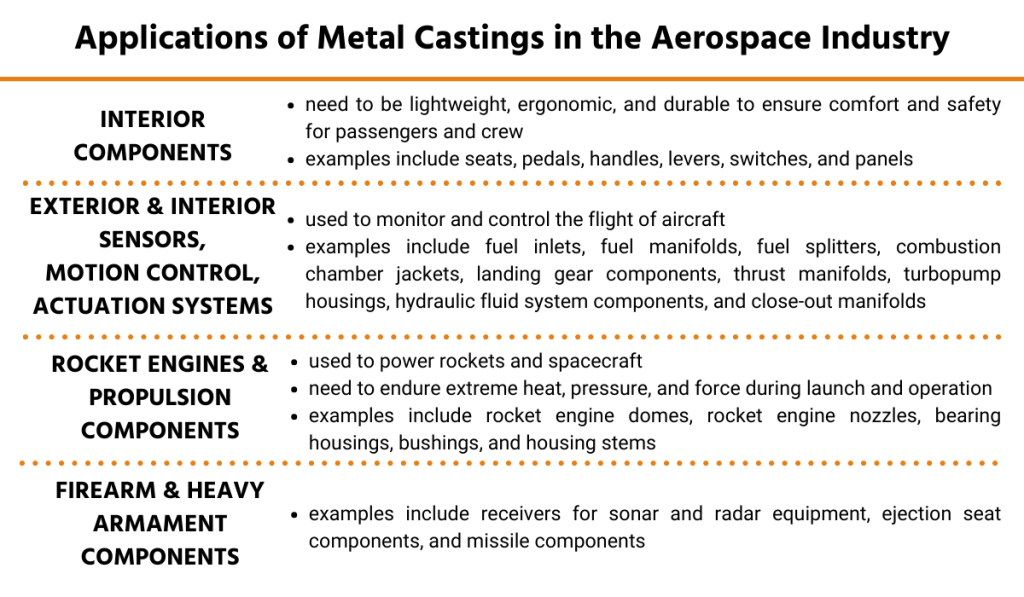

The aerospace industry relies on the metal casting process to produce high-performance, complex, and durable components for many of its applications and will look to continue and even expand on this trend for the years to come.

In 2021, the aerospace casting market was estimated at around $15,051 million and is expected to grow to $24,451.2 million by 2030.

This industry often chooses this method over others (e.g. forging, machining, and welding) since it can offer several distinct production advantages that others cannot.

For instance, metal castings provide:

These combined benefits have allowed the aerospace industry to create and improve many of the metal components it relies on to build and maintain its aircraft and other applications.

Some examples include:

As the aerospace industry continues to evolve and innovate, metal castings will most certainly remain a vital manufacturing method for many of its applications.

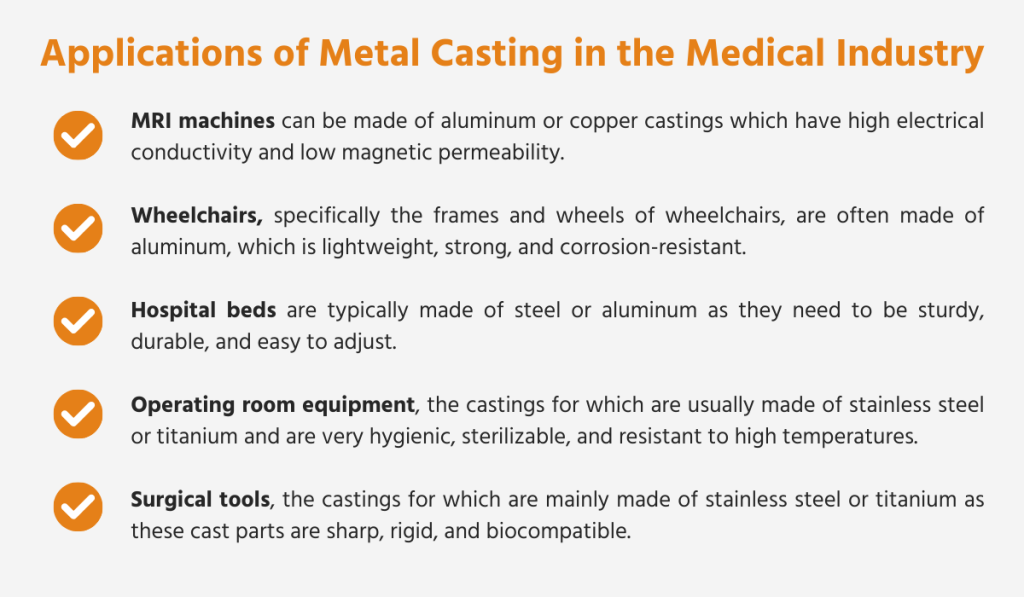

There are three factors that affect the effectiveness and reliability of medical equipment: end-user needs, ergonomics, and healthcare standard requirements.

As it turns out, metal castings exhibit the mechanical, physical, surface, chemical, and rheological properties that the medical industry requires to create sound and safe medical devices.

Three of the most important benefits metal castings provide the medical industry with include:

Due to the versatility of the metal casting process, cast metal parts can be used in a wide range of applications within the medical sector, the most common of which include the following:

The medical industry improves and saves lives, which is why it does not put the trust of the production of its tools and equipment in any random manufacturing method.

Metal castings provide the industry with durable, reliable, high-performance metal components that fulfill the quality and safety protocols for many of its applications.

The robotics industry is one of the most innovative and dynamic sectors in the world, and behind many of its advancements is a manufacturing process that produces high-quality components (i.e.metal casting).

There are a variety of reasons why the robotics industry relies on the metal casting process to build its robots and expand its technologies.

Like many other industries, the robotics sector requires metal parts with complex and intricate shapes to run many of its applications, which of course, metal casting provides.

Some of the more notable reasons this industry chooses metal casting over other production processes include:

Some of the more common examples of applications of metal casting within the robotics industry are:

As can be seen from the above examples, the robotics industry has achieved great success by using metal castings to create high-quality parts for various applications.

Robots that are made of cast metal are better able to withstand high temperatures and pressures due to their strong and durable surfaces, as well as offer strong corrosion resistance and complex geometries that help improve performance and functionality.

Metal casting is an essential manufacturing process for many industries, especially the six major ones discussed in this guide.

Its versatility, cost-effectiveness, and material flexibility allow it to create high-quality and durable products ranging from cars to buildings, from planes to implants, and from robots to tools.

Remember, though, that not all metal casting processes are ideal for all applications, which is why before giving any serious thought about using this process, we advise reaching out to custom metal casting manufacturers who have the knowledge and experience of working with the various casting methods used today to create the components that the major industries rely on.

With their help and guidance, you will receive the right casting method that best fulfills the requirements and standards of your particular metal manufacturing project.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote