Inconel, or “Inco” for short, is a superalloy composed primarily of nickel, iron, and, to a lesser extent, chromium.

When it goes through the forging process, it becomes highly resistant to oxidation, corrosion, and damage due to high temperatures.

This makes it an ideal metal for extreme manufacturing environments of high pressure and heat.

Some forms of Inconel, like Inconel 625, have higher tensile strength than some forms of stainless steel and can maintain that strength at temperatures (up to 2,000 degrees Fahrenheit) better than steel.

In the following sections, we will go into further detail about Inconel forging.

We will describe its special properties, practical applications, and the different Inconel alloys that can be formed through the forging process so you will have a better understanding of how this superalloy can potentially fulfill your manufacturing goals and needs.

Many industries, such as the automotive, aircraft and aerospace, and the oil and gas industry, require forged metals for their manufacturing needs.

The main problem with these metals is the lack of corrosion resistance that is left after the forging process is completed.

Since Inconel alloys offer superior corrosion-resistant properties, many manufactures have turned to them to build stronger and more resistant metal parts that can maintain their structural formation and offer functional versatility in a variety of harsh environments.

There are two common processes typically utilized when forging Inconel alloys:

In the first process, Annealing Inconel is first heated and then allowed to cool to lower temperatures so that it will be stronger and more stress-resistant.

In the second process, Precipitation Hardening, Inconel alloys are introduced to impurities before heating starts to boost its strength even further.

Both processes use heating to create a thick and stable surface that is protected from the effects of corrosion, oxidation, and stress.

This quality makes them ideal for high-heat, liquid, and chemical environments.

Inconel alloys have three distinctive properties that make them extremely useful in a diverse set of manufacturing conditions and applications.

Inconel metal alloys are corrosion-resistant, maintain their structure under pressure, and do not expand when exposed to extreme environmental heat.

These properties offer the following anti-stress, anti-corrosion benefits:

This superalloy can maintain its structure due to its low thermal expansion properties that not only help keep its form under high-heat forging conditions but also during high-heat applications.

Inconel can maintain its integrity in temperatures as high as 1390°C – 1425°C (2540°F – 2600°F) without melting.

Its durability, versatility, and predictability have made this special alloy the preferred manufacturing choice for many industries that require metal parts that will not bend, crack, melt, or corrode under harsh conditions.

Inconel is an ideal choice for manufacturers and design engineers within a wide range of industrial settings.

Five major industries use Inconel alloys specifically for their industrial application properties:

We’ll go over them in more detail in the following sections.

The nickel in Inconel gives it a low-expansion property that is especially useful in creating engine parts that are exposed to ongoing high temperatures and high pressure.

Airframe and jet engine components such as turbine seals and exhaust liners are made from Inconel alloys.

Inconel’s superior mechanical strength is also useful in a variety of aerospace applications like rotors, blades, and seals.

Inconel alloys are useful for oil and gas extraction since the processes employed in these applications run at high temperatures and are both volatile and corrosive.

Design engineers who work in the oil and gas processing and extraction sector prefer to use Inconel alloys for the lining of their gas extraction equipment since it allows fluids to be separated during the extraction process of liquified natural gas.

Because of their resistance to oxidation, high tensile strength (rupture & creep strength), and weldability properties, Inconel alloys are also a preferred choice for the lining of steel transfer pipings commonly used within the oil and gas industry.

Material corrosion is a common occurrence in pollution control and waste processing, which is why machine parts made of Inconel alloys are highly desirable within this industry.

Inconel alloys have a high resistance to oxidation and help to reduce acid solutions that are a common occurrence during pollution and waste applications and processing.

One of the most popular applications of Inconel in the pollution and waste industry is its use as a construction material for chemical waste storage tanks.

This is because it won’t corrode while handling and storing chemical wastes like nitric and hydrochloric acids.

As the automobile industry continuously evolves, so must the material that is used to support its technology.

Engines, for example, tend to get lighter, more efficient, and gain greater thrust as the years go by.

Such technological breakthroughs, however, still have to contend with the basic requirements needed to make automobile parts.

These include being able to withstand the high heat and wear and tear produced by friction and the burning of oil and gas.

Since Inconel is such a versatile and strong alloy, it is often used to meet such requirements.

Specifically, it is the preferred material for building ignition systems, exhaust couplings, safety devices, electrical switch gears, and sensors in many modern high-performance cars (supercars).

The marine industry consists of a broad range of sectors in both seawater and freshwater environments.

It includes, among others:

What is common to them all is the fact that the materials needed will be exposed to various types of water conditions which cause corrosion that leads to continuous replacement of materials and parts.

Inconel alloys are often used to create machine parts that are resistant to corrosion caused by water conditions.

For example, propulsion motors, propeller blades, wire ropes, platform risers, hangers, pressurized water reactors, and underwater communication cables are all manufactured with Inconel alloys.

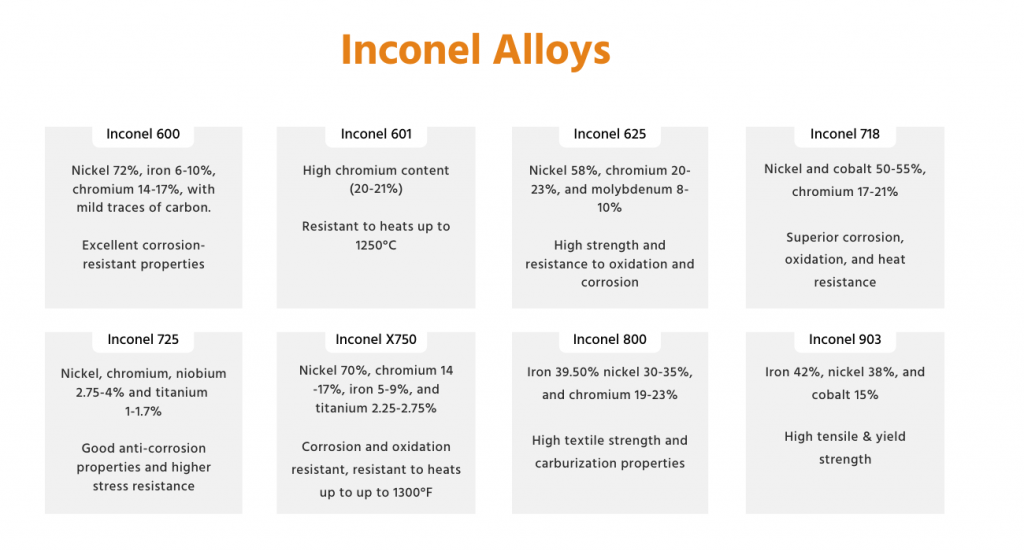

There are several types of Inconel alloy used to manufacture and produce the applications we’ve mentioned above.

Although they are all rather similar in their general properties and qualities, each type has distinctive features that make them ideal for specific applications.

We’ve listed eight different Inconel alloys and their special characteristics and applications below, so you can make a more informed decision as to which one is most conducive to your manufacturing goals.

This alloy offers the perfect combination of versatility, strength, and resistance to corrosion making it one of the more popular alloys across many industries and applications.

Inconel 600 was first introduced by metallurgist Adolph Machlet in the 1930s.

It is composed of nickel (72 percent), iron (6 to 10 percent), and chromium (14 to 17 percent) with mild traces of carbon added to the mix.

Inconel 600 is used in the following applications:

Inconel 600’s excellent corrosion-resistant properties, good tensile strength, and easy weldability and machining have made it popular within the aerospace, chemical, and nuclear industries.

Inconel 601 is a useful alloy for industries that face extreme environments due to its strength and resistance to high temperatures.

Its high chromium content (21 to 25 percent) makes it resistant to heats up to 1250°C, and its aluminum content gives it a high resistance to oxidation.

Inconel 601 alloys are used in the following applications:

Because of its high heat resistance, excellent strength, and anti-oxidation properties, it is widely used for interior linings and component parts within the aerospace, chemical/thermal, power generation, and metal & glass industries.

This Inconel alloy has remained a standard construction material for a wide variety of industries since it was first introduced in the 1960s because of its balanced composition.

Inconel 625 is a mixture of nickel (58 percent), chromium (20 to 23 percent), and molybdenum (8 to 10 percent).

The balanced combination of nickel, chromium, and molybdenum gives this alloy its incredibly high strength and resistance to oxidation and corrosion, especially crevice and pitting corrosion.

Inconel 625 is commonly used in the following applications:

Its large number of balanced properties (corrosion, high-heat and saltwater resistance, easy weldability, high tensile strength, and creep and rupture strength) make it one of the most popular construction materials for many applications within a variety of industries.

This alloy is a great manufacturing choice if you need a material that can retain its structure, integrity, and strength over a wide temperature range.

The combination of nickel and cobalt (50-55 percent), as well as chromium (17 to 21 percent), gives Inconel 718 the strength to withstand high temperatures up to 1300°F/704°C, as well as offer superior corrosion and oxidation resistance.

Inconel 718 is popularly used in the following applications:

Since this alloy can maintain its integrity under high heat and atmospheric and mechanical stress it is primarily used in the aerospace and aviation industry.

However, as it maintains the same integrity under cooler temperatures, it is also used within industries that require cryogenic tankers to store and move their manufacturing gases.

Like Inconel 625, Inconel 725 has good anti-corrosion properties but with the added benefit of higher stress resistance.

Like many of the other Inconel alloys, Inconel 725 is mainly composed of nickel and chromium but also contains significant amounts of niobium (2.75 to 4 percent) and titanium (1 to 1.7 percent).

As a result, it is two times stronger than Inconel 625.

This super-strength alloy is used in the following applications:

Inconel 725 is mainly used in the marine and petroleum and natural gas industries because of its blend of super-high strength and ability to stave off corrosion caused by seawater and natural gas.

The properties of Inconel X750 make it an ideal choice for projects that require high-strength and high-temperature corrosion resistance.

Inconel x750 is hardened through the use of precipitation and consists of nickel (70 percent), chromium (14 to 17 percent), iron (5 to 9 percent), and titanium (2.25 to 2.75 percent).

This alloy is suited for many industrial applications due to its corrosion and oxidation resistance, as well as its extremely high strength that can tolerate temperatures up to 1300°F.

Inconel X750 is popularly used for the following applications:

Since it has a variety of useful properties, specifically its high-strength capability, Inconel x750 is used within the aerospace, oil & gas, and nuclear industries.

Inconel 800 is more of a series of alloys rather than a singular one, including Inconel 800H and 800T.

It was originally designed in the 1950s for projects in high-temperature and highly corrosive environments.

Since then, the two newer versions have been created to offer more creep and rupture strength, specifically for petrochemical applications.

The Inconel 800 series of alloys consists primarily of iron (39.50 percent), nickel (30 to 35 percent), and chromium (19 to 23 percent).

They are used in the following applications:

The 800 series of alloys have a high degree of textile strength and carburization properties. They are also resistant to oxidation and do not corrode even in acidic environments.

As such, they are ideal for the harsh and demanding environments of the aerospace, marine, and chemical industries.

This nickel-cobalt alloy is prized for its strength (1200ºF/650ºC), low thermal expansion, and oxidation resistance.

The combination of iron (42 percent), nickel (38 percent), and cobalt (15 percent) give Inconel 903 its high tensile & yield strength (1310 MPa/1100 MPa), low thermal expansion (7.65 µm/m°C/4.25 µin/in°F), and easy forming, welding, and annealing properties.

Inconel 903 is primarily used in the following applications:

The material’s low expansion coefficient and ability to not crack, bend, or melt under high temperatures have made it useful for many components and machine parts in aerospace, oil and gas, electric power, and manufacturing industries.

What makes Inconel alloys so special is their durability and predictability under the harsh environments of industrial settings.

Because of their resistance to high oxidation and corrosion, creep resistance, and the ability to maintain structure under extreme temperatures, the Inconel series of alloys are an ideal material for many industrial manufacturing projects.

Engineer designers often turn to these reliable superalloys.

They use them to make components and parts that can withstand the hottest and coldest of temperatures and the wettest and most acidic of environments.

If you need a dependable and long-lasting metal that won’t corrode and oxidize in wet, gaseous, and acidic environments, or melt in severe temperatures, and crack under extreme stress, then consider forging Inconel alloys for your next manufacturing project.

If you’d like to find out more about our forging services, contact us directly via the convenient website form or request a quote here. We welcome your inquiries.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote