Inconel 625 (also known as Haynes 625) is a superalloy that is prized for its high performance under severe conditions as well as its versatility of use.

It was created back in the 1960s for the express purpose of manufacturing steam-line piping which is used in turbines and steam engines.

However, manufacturers soon discovered that its many useful properties can find purpose across multiple industries, and the demand for it increased.

The following sections will cover some of the most important facts about Inconel 625, including its composition, properties, manufacturing capabilities, and applications.

This information will help you decide if this superalloy is a good fit for your custom metal parts.

It is unusual for an alloy to have widespread use in a multitude of different applications, yet Inconel 625’s chemical composition gives it a unique set of physical and mechanical properties that make it a good fit for many industrial settings.

To begin with, most alloys need to go through extra manufacturing processes to protect them from damaging substances and environments, which often make them a more expensive option than pure metal.

However, with Inconel 625 that is not the case, as the alloy’s ability to withstand such substances and environments stems from the elements that comprise it.

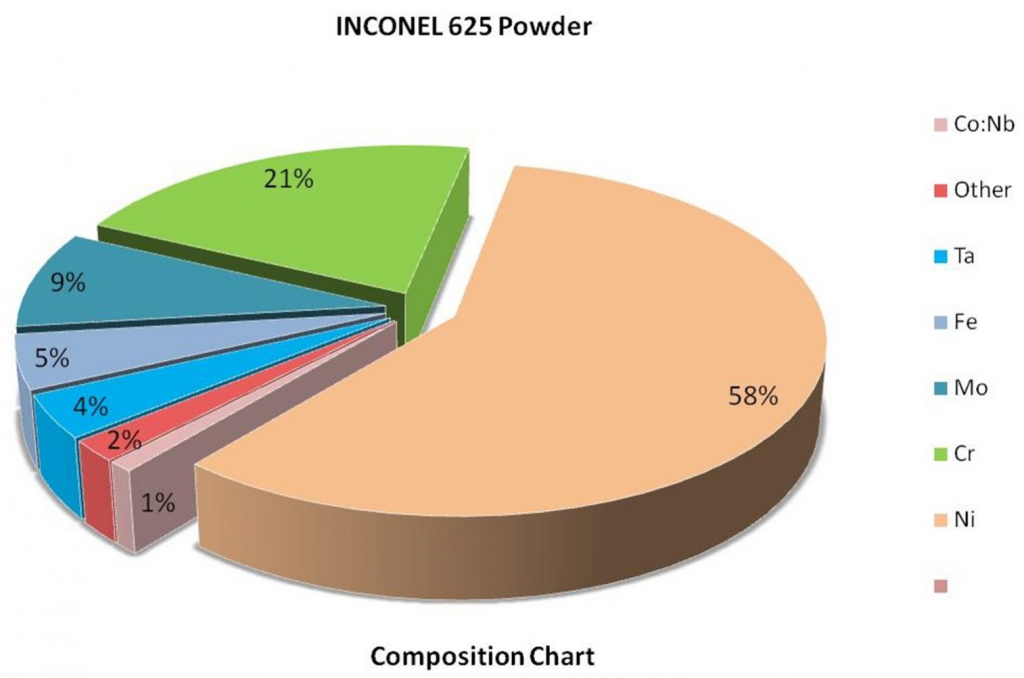

The base metals, nickel, chromium and molybdenum, display useful properties which are further enhanced by those of the other elements that comprise the alloy.

Here is an overview of those properties:

| Nickel | corrosion resistance, strength, malleability, and ductility. |

| Chromium | high thermal expansion, high melting point, and stable structure |

| Molybdenum | strength, hardness, electrical conductivity, and corrosion resistance. |

In short, the alloy combination of the above metals, along with the other elements previously listed, gives Inconel 625 an excellent balance of high strength, resistance to high temperature and corrosion resistance.

Out of these three properties, perhaps the most sought-after one is corrosion resistance, as no other form of damage can immobilize and break down equipment, components, and structures like corrosion.

The cost of corrosion damage among all industries and all nations is estimated to be around $2.5 trillion, which is why a material that has a high degree of corrosion resistance is so necessary for manufacturing metal parts that operate in corrosive environments.

The breakdown of the global cost of corrosion can be seen in the table below:

Corrosion damage can appear in a variety of forms. Perhaps the most common one is rust, which appears in iron and steel.

In addition to discoloration, which affects the aesthetics of the product, corrosion also leads to equipment deterioration and failure, resulting in a lack of functionality.

To mitigate these effects, many metals and alloys are reinforced with special coatings that add a layer of corrosion protection to their surface.

However, as Inconel 625 is an alloy, it already exhibits a high degree of corrosion protection—as mentioned earlier, it is an amalgamation of metals and non-metals which already have corrosion-resistant properties so no extra coating is required.

During the alloying process, metal alloys such as Inconel 625 form a protective layer on their surface that does not allow oxidation, one of the main causes of corrosion, to occur.

Not only does Inconel 625 prevent general corrosion and oxidation but its external and internal surfaces are resistant to a host of other highly-damaging occurrences such as:

Thus, Inconel 625’s outstanding corrosion resistance makes it an ideal material for the manufacturing of custom metal parts that will be exposed to oxidizing environments, non-oxidizing environments, aqueous environments, and even sensitization.

The latter commonly occurs during the welding process and results in both intergranular corrosion and stress corrosion cracking.

During welding, different metals are joined (fused) together by heating them to their melting point.

Inconel 625 has a high degree of heat tolerance, and therefore it seems obvious to assume that it would be impossible or, at the very least, extremely difficult to weld it.

Inconel 625’s melting point is anywhere between 2,350 Fahrenheit (1,290°C) to 2,460°F(1,350°C), which would thoroughly melt many other forms of metal during a weld.

However, it is not impossible to weld Inconel 625, provided that it is done correctly—in a way that won’t burn, crack, or melt the two joined metal pieces during the process.

The following three tips will ensure that the welding of your Inconel 625 is done correctly and without damaging the Inconel part or the adjoining metal part (carbon steel, stainless steel, etc.) it is being fused with.

The TIG welding process uses a high-temperature electrode that will not melt during welding, even at temperatures as high as Inconel 625’s melting point.

Even though a filler material (welding wire) is not strictly necessary during TIG welding, it is advisable to use one to lessen the occurrence of cracking due to extreme heat.

Using an Inconel 625 welding wire will be the best choice for welding Inconel 625.

This is because using a different metal wire that is dissimilar to the material to be joined will almost always damage the joined materials during a high-heat TIG weld.

Thermal expansion and galvanic corrosion tend to occur when dissimilar welding wires are used during TIG welding.

Hand-welding is very inconsistent and often produces sloppy welds as the welder gets tired and hot after repeated welds.

Instead, use an automated welding machine to increase safety (robots don’t get burned), consistency (robots don’t get tired), and quality (robots weld with exact precision).

By using the above tips to weld Inconel 625, it is possible to avoid common welding defects like solidification cracking and weld porosity.

Post-welding heat treatment compliments the welding process as it helps reinforce the strength of welded joints.

Post-heat treatment helps to soften any structural hardening that may occur during welding.

What is more, heat treatment can add many enhanced properties to Inconel 625, such as:

However, to achieve such benefits, the heat treatment being employed must be compatible with Inconel 625’s chemical composition and desired properties.

There are three types of heat treatments that work well with Inconel 625: high solution anneal, low solution anneal, and stress relief.

A description of each type has been given below.

This treatment uses a lengthy high heat process (2,200°F/ 1205 °C) followed by a cooling and soaking period of up to one hour.

It is ideal for Inconel 625 components that work in high temperatures (1,500 °F/ 815 °C) and require a good degree of creep resistance.

This heat treatment process uses a lower heating temperature than the previous one (1,900 °F/ 1,040 °C) but maintains the same soak time of one hour.

It helps provide a balanced combination of rupture and tensile strength in ambient temperatures, as well as optimal ductility and toughness in low temperatures (cryogenic atmospheres).

This treatment also uses a one-hour soak and cooling time which is employed after heating welded metals at a temperature of 1,650 Fahrenheit (900 °C).

It helps enhance fatigue strength, tensile strength, ductility, and toughness in temperatures as high as 1,200 °F (650 °C) and as low as -130 °F (-54 °C).

The three heat treatments listed above help Inconel 625 obtain those desired mechanical properties that are suitable for specific applications that operate in both low and high temperatures.

Finishes are coatings that are added during or after heat treatment to increase aesthetics and prevent environmental issues.

They can enhance the corrosion protection of Inconel alloys by adding an extra layer to their substrate (surface).

While Inconel 625 already has a good balance of desirable properties, adding a finish to it could make it that much more appealing as well as reduce any unwanted surface defects.

However, applying finishes to Inconel 625 can be difficult. Therefore, it is important to select a coating method that won’t damage or limit desired physical and mechanical properties.

Six general finishes can be applied to most metals and alloys.

These include:

Since Inconel 625 is already complete in and of itself, the above finishes are usually not needed.

In fact, they could even interfere with its microstructure and underlying properties if applied.

However, an extra coating may be beneficial or even required by the manufactured component.

So, to ensure that structural integrity, as well as physical and mechanical properties, stay intact, the following three finishes may be applied without fear of damage or loss:

A brief description of each is given below:

This coating process uses metal, cement, ceramic, and polymer deposits in thick layers to cover and bind the coating with metal surfaces.

Almost any material that melts can be used during thermal spraying.

The main benefit of using this finishing process lies in its ability to spray alloys and metals with high melting points, which Inconel 625 has.

This coating deposition method uses supersonic gas jets to spray solid powders on metal surfaces and therefore no melting process is needed, as in the case of thermal spraying.

Materials such as metals, polymers, composite materials, and nanocrystalline powders can be used during cold spraying.

Some of the benefits of using this method are higher levels of thermal conductivity, electrical conductivity, density, hardness, and an even spray over the underlying substrate.

This process uses a laser to heat and spray metal coatings (nickel alloy, cobalt alloy, tungsten carbide) to metal surfaces.

Laser coating finishes do not damage or dilute the base metal, thus ensuring the integrity of its structure and properties.

Additional benefits of using laser coatings for Inconel 625 finishes include enhanced corrosion resistance, wear and tear resistance, and smooth finishes.

While all three finishing methods work well with Inconel 625, you should not make your choice before consulting with a metal parts manufacturer like Bunty.

After all, professionals are best equipped to match the right finish that will fulfill your specific project requirements.

For over half a century, Inconel 625 has been chosen to build a variety of applications across numerous industries.

However, it is largely prevalent across four industries:

With a solid track record in multiple industries, Inconel 625 is sure to remain increasingly popular in years to come.

For instance, the world’s waste problems have increased demands for resilient materials like Inconel 625, which can withstand the highly corrosive environments found in the waste management industry.

This superalloy is also expected to become a key player in the ever-increasing solar energy industry as it can withstand the excessive heat of the hot salts and corrosiveness of the potassium and sodium that are used to power electric generators at solar power plants during the night.

Inconel 625 can protect equipment in industrial applications against corrosion, high temperatures, and heavy stress loads.

Moreover, its tough exterior, functionality, and versatility can be increased when subjected to manufacturing processes like welding, heat treatment, and the application of different finishes.

It can withstand extensive stress and high temperatures, as well as corrosion and oxidation.

Since it is corrosion resistant in high and low temperatures, and in and out of aqueous settings, it is a good choice for building components intended for harsh environments such as those found in the nuclear and marine industries.

If your custom-metal parts require materials that can provide strength, durability, machinability, and functionality in the hottest and most highly acidic of settings, contact a metal manufacturer like Bunty.

We work with Inconel 625 and offer those added manufacturing processes that can enhance its properties even further.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote