Hastelloy and stainless steel are both alloys that are widely used in a variety of industrial applications which require high-strength and strong corrosive-resistant properties.

In spite of those similiarities, they differ quite a bit in their chemical composition, properties, and the specific applications and industries in which they are used.

In the following sections, we shall cover the key differences between these two popular alloy manufacturing materials.

We will discuss the main distinctions between their characteristics, composition, manufacturing processes, applications, and price.

In short, we’ll give you all the information you need to identify which one suits your needs best.

As we’ve said, Hastelloy and stainless steel both have excellent corrosion-resistant properties. However, Hastelloy has a slight advantage in this regard, because of its high nickel content.

Nickel, which is the primary element found in Hastelloy, has a melting point of 2,651ºF (1,455 ºC), giving it excellent anti-corrosion properties, high-temperature strength, and good electrical resistance.

Stainless steel also has good corrosion-resistant properties due to its nickel and chromium content. However, it is its iron and carbon content that gives it a wider range of properties that are particularly useful in applications requiring structural strength and aesthetic appeal.

Below you will find a breakdown of the primary properties of both these alloys.

| Hastelloy Properties | Stainless Steel Properties |

| Excellent Corrosion Resistance Electrical Resistance High-Temperature Strength Good Mechanical Properties Stress Resistance Good Ductility | Corrosion Resistance High Tensile Strength Temperature Resistance Good Ductility High Durability Low Maintenance Attractive Appearance |

As you can see from the chart, although the two materials share some common properties, they differ in many ways. These disparate characteristics make Hastelloy more suitable for some applications, and stainless steel for others.

Namely, Hastelloy is one of the best alloy manufacturing choices for corrosive environments, while stainless steel is ideal for applications that require structural integrity.

The similarities and differences in properties between Hastelloy and stainless steel are directly influenced by the elements found in their compositions. The following section will touch upon these distinctions in further detail.

Before going into the specifics of the main and auxiliary elements that make up Hastelloy and stainless steel, it is important to understand that Hastelloy is a nickel-based superalloy and stainless steel is an alloy that is primarily composed of iron and carbon.

Let’s define those terms.

Alloys consist of a metal and two or more elements (metals or non-metals), while superalloys are made up of several high-performing alloys that are known for their high-temperature resistance.

Both alloys and superalloys are made up of more than one element. Alloys are made from metals and other non-metal elements, which give them desired properties that are useful for specific applications.

On the other hand, superalloys are primarily composed of other alloys that accentuate each of their unique properties.

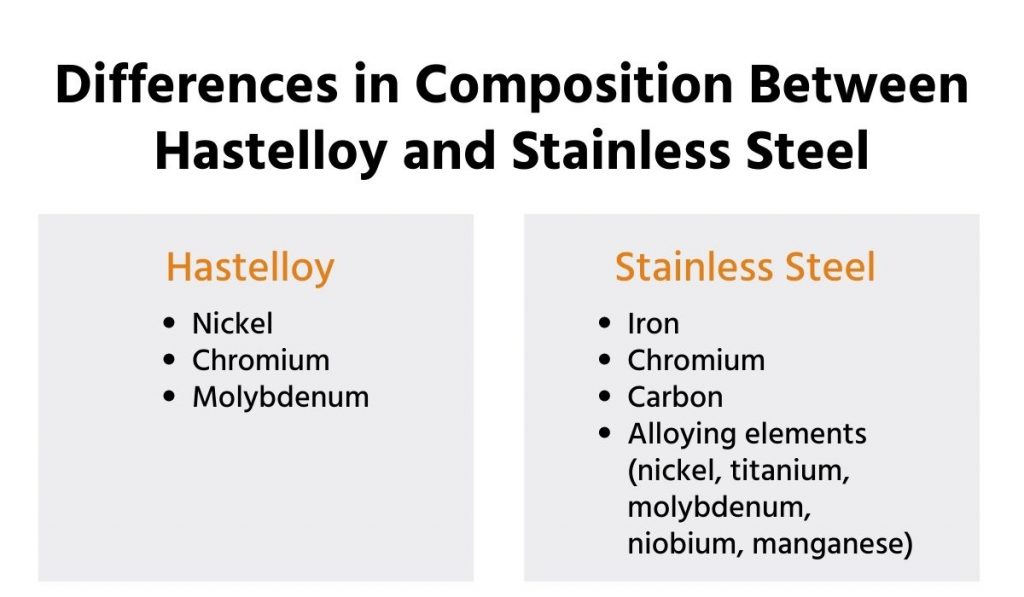

Now, let’s take a look at the differences in composition between stainless steel and Hastelloy.

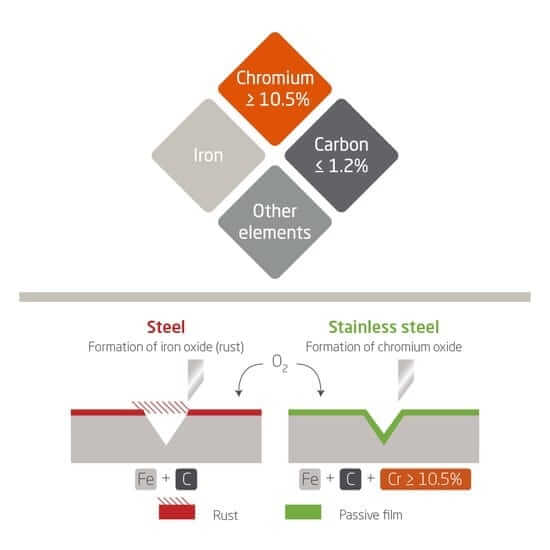

This is what stainless steel is composed of:

The main difference between steel and stainless steel is the addition of chromium (210.5%), which gives stainless steel extra corrosive-resistant properties.

Alloying elements like nickel and molybdenum are also added, giving it additional strength, toughness, malleability, ductility, and fatigue resistance).

This is the basic composition of Hastelloy:

While it contains a high amount of nickel and molybdenum, there are many grades of Hastelloy that have secondary elements in them like iron, tungsten, cobalt, copper, manganese, phosphorus, vanadium, silicon, and sulfur.

Those additions give each one a specific set of properties which makes them useful for various applications.

The foundational elements in the two materials also shape their properties.

As mentioned earlier, in the case of Hastelloy, those are nickel and molybdenum, and in the case of stainless steel, iron and chromium.

Hastelloy has a higher melting point, whereas stainless steel has higher tensile strength ( 621 MPa or 90 KSI) and better rust resistance.

The rust resistance is particularly notable in environments where nitric acid is prevalent.

Since both materials contain different elements in different quantities, each one has to undergo a unique manufacturing process. These distinctive processes will be the main discussion in the following section.

Hastelloy is created by mixing basic ingredients (nickel and molybdenum) with other chemical elements (i.e., tungsten, carbon, cobalt, etc.) through a dissolution process called solid solution strengthening, or solid solution hardening.

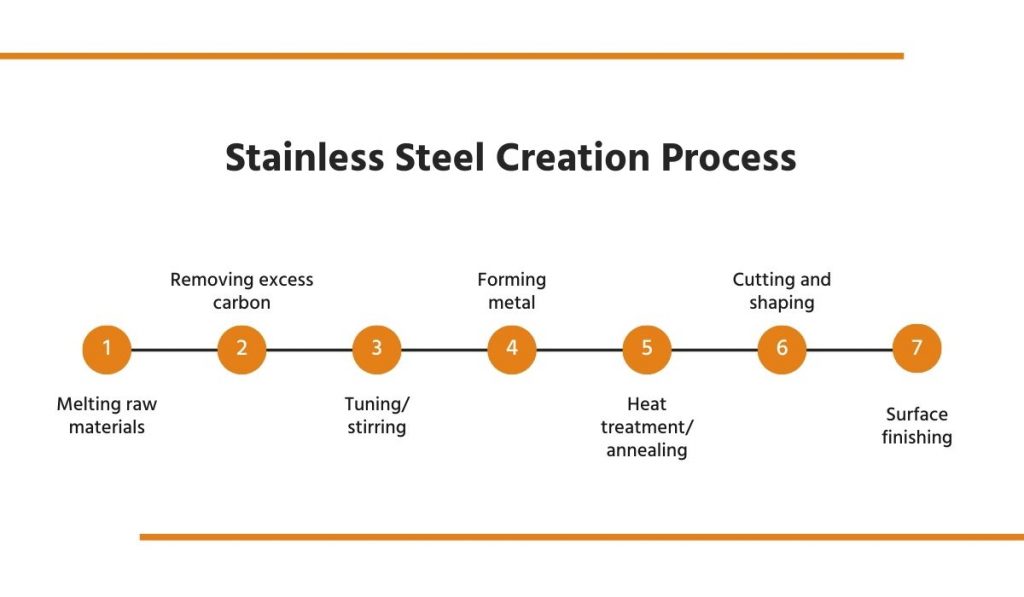

Stainless steel, on the other hand, involves a multiple-layer process that involves seven basic steps:

The following is a summary showcasing the differences between both their manufacturing processes and the way those processes affect their eventual characteristics.

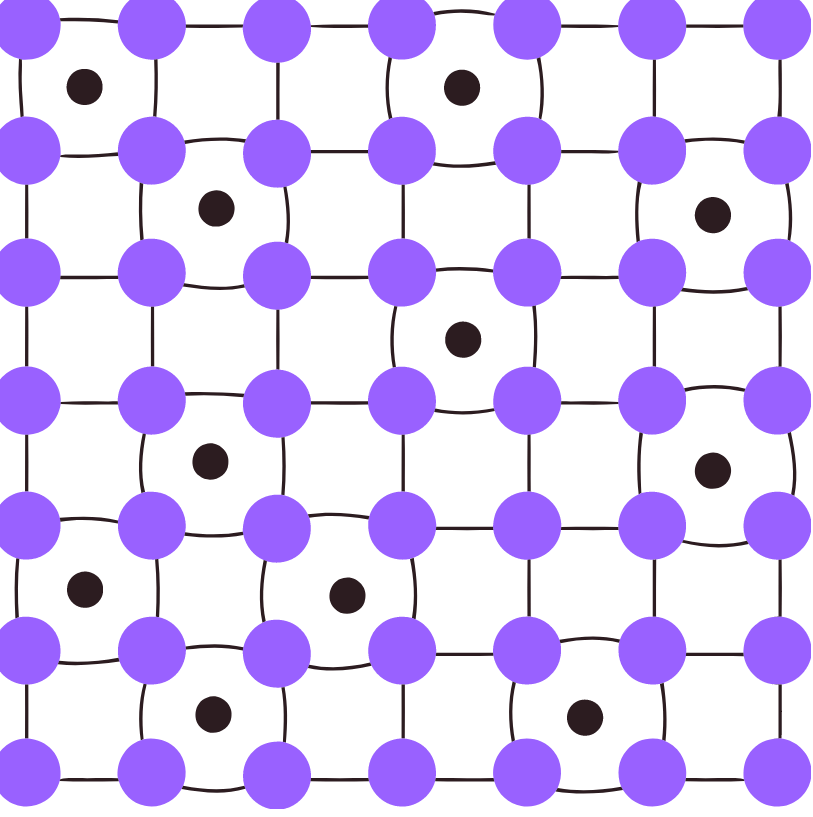

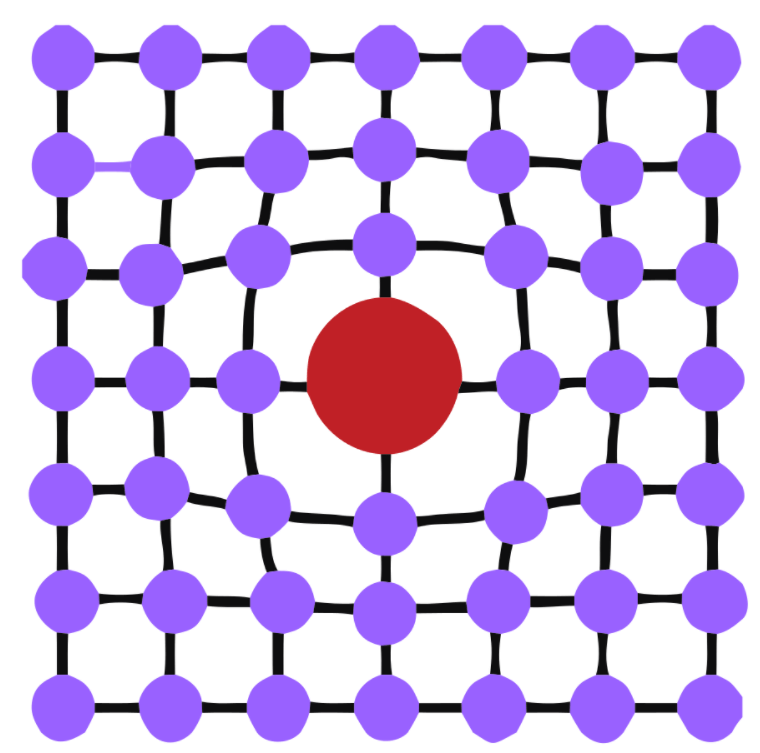

As was mentioned earlier, Hastelloy is created through an elemental and chemical mixture process called solid solution strengthening. This process can be done using two solution methods—either through an interstitial solid solution or a substitutional solid solution.

A brief description of each is given below.

In an interstitial solid solution, a primary solute atom is embedded (localized) between other solvent atoms (i.e., molecules that can dissolve other molecules) within the solution.

That way, the forming elements compress and strengthen the structure.

In a substitutional solution, a larger solute atom is used to replace other solvent atoms that are located across the lattice of the solution to give Hastelloy more soluble and volumetric features (i.e., increased volume).

The choice of strengthening solution in producing Hastelloy entirely depends on the desired properties the superalloy is to have as defined by the end user.

For example, if basic volume is needed, then a substitutional solution is preferred. However, if further strength is required, then interstitial solutions are the best choice.

The basic seven-step manufacturing process used to create stainless steel is described below.

Keep in mind that there are three additional steps that may be included, depending on the application. We’ll touch upon some of them in the following sections.

The melting process involves placing the different materials (metals and non-metals) into a furnace for eight to twelve hours until the combined material reaches its melting point.

The molten metal is placed in either a vacuum oxygen decarburization (VOD) or argon oxygen decarburization (AOD) system to remove any excess carbon.

This results in the creation of a standard or low-carbon stainless steel alloy, raising or lowering the level of tensile strength and toughness of the final product.

During this step, the molten steel is turned (stirred) to distribute or remove unnecessary stainless steel components.

That way, the final product remains uniform and has those specific properties that meet the requirements of the end user.

While the steel is cooled, different forming methods like hot rolling and cold rolling are used to make the steel tougher and create different surface finishes like blooms and billets.

The fifth step helps to relieve stress and change the mechanical properties of the steel by annealing (heating and cooling) the steel under controlled conditions.

An additional descaling procedure may be required during this step if more oxidation protection is needed.

After annealing the stainless steel, it is cut and shaped to desired specifications using a variety of cutting machines (e.g., CNC punch, cutting lasers).

Different surface finishes may be applied during the seventh and final step to make the stainless steel smoother. However, the most common finish is simply to grind the surface down sufficiently enough to remove any remaining impurities.

The different processes used in the production of Hastelloy and stainless steel, combined with their different compositions, are what gives them their unique properties. These properties make those materials suitable for different applications in several industries.

The different industries and applications where stainless steel and Hastelloy are most commonly used will be the topic of the next section.

Stainless steel and Hastelloy have many uses in a wide variety of structures, products, and equipment we use today.

Stainless steel, however, has a wider range of uses as its properties allow it to be used in a host of products that people use daily.

Here are the main industries that utilize stainless steel:

The table below lists the most common applications of stainless steel in some of the industries we’ve mentioned.

| Construction and Architecture | Exterior Claddings Interior Countertops Handrails Backsplashes Bridges/Monuments/Structures Airport Roofs |

| Cutlery & Kitchenware | Forks, spoons, kitchen knives Cookers Grills Sinks Saucepans Finish Material (refrigerators, freezers, countertops, dishwashers) |

Oil/Gas & Chemical | Tanks Pipes Pumps Valves Propellers Chemical Storage Containers |

| Power Generation | Turbines (steam, gas) Hydropower Components Solar Power Components Wind Power Components Geothermal Components Radiation Containers |

| Automotive & Aerospace | Car Exhaust Systems Auto Parts (hose clamps, seatbelt springs) Fuel Tanks Suspension Components Chassis Catalytic Converter Applications Aircraft Parts (springs, castings, tie rods, control cables) |

| Medical Equipment | Hemostats Surgical Implants Temporary Crowns (Dentistry) |

Stainless steel’s corrosion-resistant, high-strength, and low maintenance properties have made it a useful metal for many of the appliances we use today, as well as a lot of machinery used in industries that operate in harsh environments like the chemical, oil and gas, and power generation industries.

Hastelloy too has many uses in a variety of industries but more so for those that operate in highly corrosive environments and less so for those that supply appliances for daily use.

Let’s list some of the industries where Hastelloy is used:

Hastelloy is used in the creation of a variety of products within these industries, and the table below lists some of them.

| Oil & Gas | Gas Wells Oil Wells |

| Chemical & Petrochemical | Columns Heat Exchangers Pressure Vessels Piping Systems Various Reactor Equipment |

| Power Generation | Gas Turbine Combustors Gas Turbine Exhausts Coal-Powered Plant Components Coal-Powered Plant Equipment |

| Aerospace | Fuel System Parts Exhaust Ducts/Nozzles Flame Holders Afterburners Various Aircraft Parts (ring, seals, cases, shrouds, diffusers, manifolds) |

| Pharmaceutical | Active Pharmaceutical Ingredients (API) Buffer Solutions |

Other industries, like the marine and automotive, that would normally benefit from using Hastelloy due to its outstanding corrosive-resistant properties, sometimes rely on other, more cost-effective alloys.

While the properties and characteristics of alloys are one of the most important factors in their purchase and use, another highly important one is cost, which is the topic of the next and final section.

Which one is more expensive, Hastelloy or stainless steel?

The quick answer is Hastelloy, and for good reason. Let’s take a closer look at the actual differences in cost, why they are priced the way they are, and long-term benefits.

Hastelloy is more costly than stainless steel because the material used to create it is more expensive in itself. Moreover, the manufacturing process used to form it is more sophisticated than the material and creation process used to make stainless steel.

Nickel, the base metal used to form Hastelloy, is significantly more expensive than other ferrous metals, including iron. In fact, at the time of writing this post, one pound of nickel cost over $9.

Nevertheless, even though the upfront cost of Hastelloy may be higher than that of stainless steel, nickel-based alloys tend to last longer than iron-based alloys.

This is particularly true in highly corrosive environments. So, if corrosion resistance and longevity are primary concerns for you, then Hastelloy may be cheaper in the long run.

Stainless steel may be more expensive than the other grades of carbon steel due to the additional alloying elements that are added to it.

However, it has higher corrosion resistance and is very low maintenance, which makes it the less expensive choice when life-cycle and maintenance costs are factored in.

Compared to Hastelloy, stainless steel has a lower upfront cost and can even outlast it under normal conditions, since it can be expected to last over 100 years.

However, it should be noted that, under highly corrosive conditions, it does not have a longer life cycle than Hastelloy.

At the time of writing, iron, which is the foundational metal found in stainless steel, cost around $0.04680 per pound.

To sum up, while Hastelloy may be more expensive initially, in highly corrosive environments (such as those that can be found in the chemical, petrochemical and aeronautical industries), it is a more cost-effective and durable manufacturing material.

Stainless steel, on the other hand, is not only less expensive to use for more public applications (e.g. construction, architecture, kitchenware, and surgical tools) but also more practical.

It maintains its strength and flexibility for a long time, it is very easy to weld, and provides an attractive finish.

Stainless steel and Hastelloy both have great corrosion protection but the fact that they contain different elements in different quantities makes one more suitable for some industries and applications and the other for different ones.

The above sections have given you a good idea of the main differences between the two alloys in regards to their properties, composition, manufacturing process, applications, and price, all of which will help you in your selection process.

Whichever of these materials you opt for in the end, we still strongly suggest that you consult your metal parts manufacturer before making a purchase decision between the two.

After all, professionals are in a better position and more highly qualified to help you choose which one is better for your specific needs and requirements.

For further information about which type of material would be best suited for your project, contact us via the convenient website form or submit a request for quote directly.

We welcome your inquiries.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote