Inconel and Hastelloy are used in a variety of industries to produce custom metal parts that can function in elevated temperatures.

Both of these superalloys belong to the family of nickel and chromium alloys, and they’re ideal manufacturing materials for application in harsh environments.

Even though they are quite similar in many regards, they both have distinctive compositions that determine which applications they’re more useful in.

Below, we will go over the specifics of both of these classes of alloys and their distinct differences so you can decide which one will be more practical for your specific situation and applications.

Hastelloy is a solid-solution strengthened alloy composed primarily of nickel, chromium, iron, and molybdenum.

Compared to pure metal, it boasts improved features such as high-temperature resistance, good oxidation resistance, and outstanding stress-corrosion resistance.

The Hastelloy class of superalloys was made specifically to be applied in welding, and used in chemical environments due to their highly-corrosive and high-temperature resistant structure.

Some of the most distinctive manufacturing features of Hastelloy alloys include their weldability, machinability, and ductile nature.

This makes them a very useful material for manufacturing custom metal parts within the chemical, petrochemical, and nuclear industries.

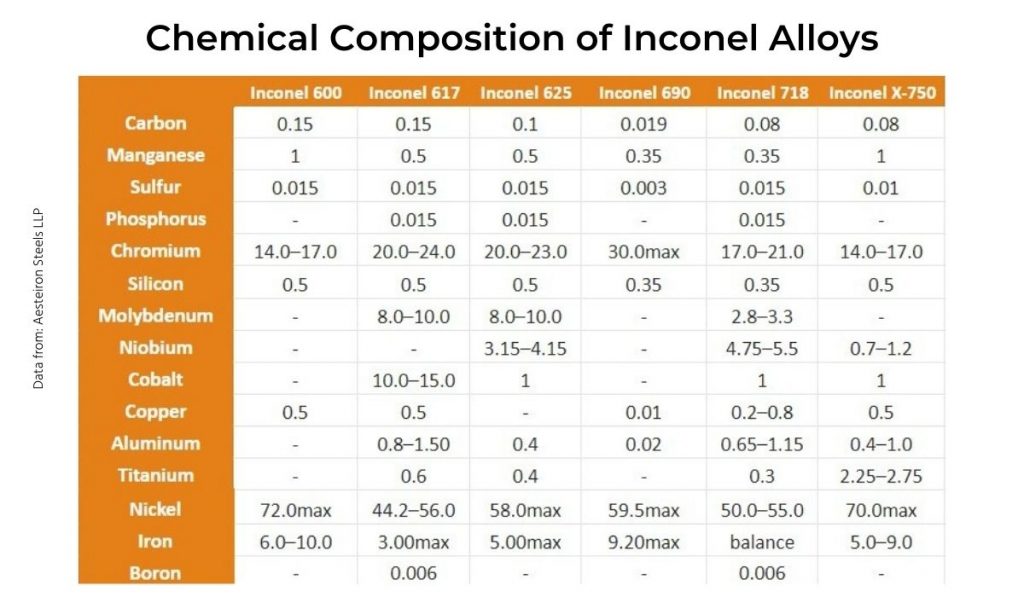

The name Inconel is a trademark name referring to a group of nickel-base superalloys whose chemical composition consists of nickel, cobalt, molybdenum, titanium, and niobium.

Since Inconel alloys consist of a group of superalloys instead of just one superalloy, their chemical composition varies across the group. However, all of them include nickel as their primary composite.

Its nickel foundation, along with its other varying chemical components, make this group of alloys well-suited for use in conditions of extreme heat and pressure.

This is because Inconel alloys form a tough, thick, and oxide-resistant surface when they are treated through either solid solution strengthening or precipitation hardening.

Due to their extremely high tensile strength (103-160 ksi/14-1,103 MPa), which is maintained even under very high temperatures (1,800°F, 982°C), they are often chosen over pure steel and other superalloys for heat-treating applications and very high-temperature processes.

As with their composition and basic properties, the creation process of both Inconel and Hastelloy share some similarities but also differ in some regards.

Before discussing how they differ in composition, let’s look at how they are made.

This will ultimately affect their final composition and what applications they are best suited for.

As was mentioned earlier, Hastelloy is made using a process called solid solution strengthening (a.k.a.solid solution hardening).

This is when elements like cobalt, molybdenum, chromium, copper, tungsten, titanium, aluminum, and manganese are mixed into the primary nickel-base ingredient.

In the process of solid solution hardening, atoms of alloying elements are added to the base metal (e.g., nickel) to improve the overall strength (tensile strength, impact strength, compressive strength, melting point, and operating melting point) of the superalloy being created (i.e., Hastelloy).

The process of solid solution strengthening can be done in two ways—through a substitutional solid solution or an interstitial solid solution.

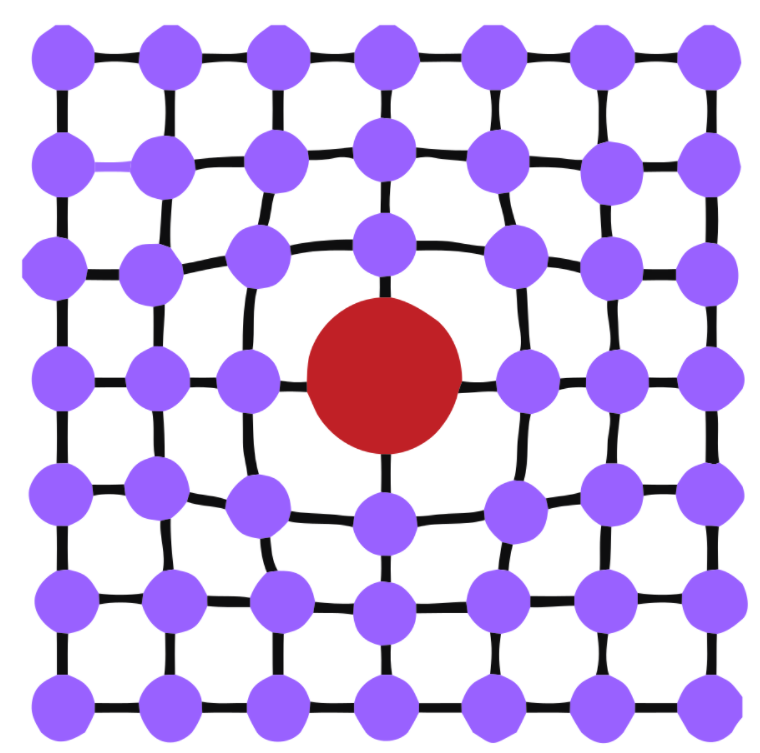

In a substitutional solid solution, the primary solute atom is large enough to replace other solvent atoms in the lattice positions, giving the composition a higher solubility feature.

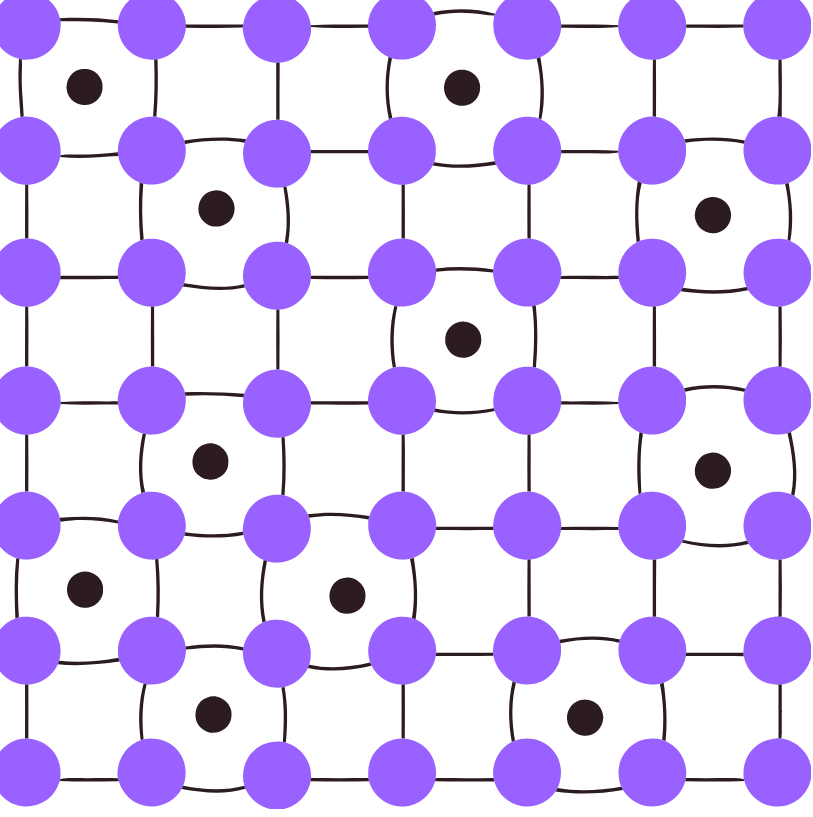

In an interstitial solid solution, the main solute atom is small enough to localize itself between the other solvent atoms, leading to a more compressed and stronger structure.

In both of these processes, the lattice is distorted to the point where dislocation movement is almost impossible, mitigating defects and distortions, as well as raising overall stress resistance.

It should be noted that solid solution hardening is used to form all three different types of Hastelloy grades: B, C, and G-Type Hastelloy.

Although each of these Hastelloy types is created through the same solid solution strengthening methods mentioned earlier, slight variations to both processes increase the corrosion resistance, stress resistance, or temperature resistance to suit the needs of the specific application or process they are being used for.

Just like Hastelloy, Inconel alloys can be made using solid solution strengthening.

However, they can also be created through a process known as precipitation hardening, which enhances the hardness, strength, and machinability of alloys.

Since the solid solution hardening process was already discussed, we will focus on the second method—precipitation hardening—and see how it creates and improves the features and functionalities of Inconel alloys.

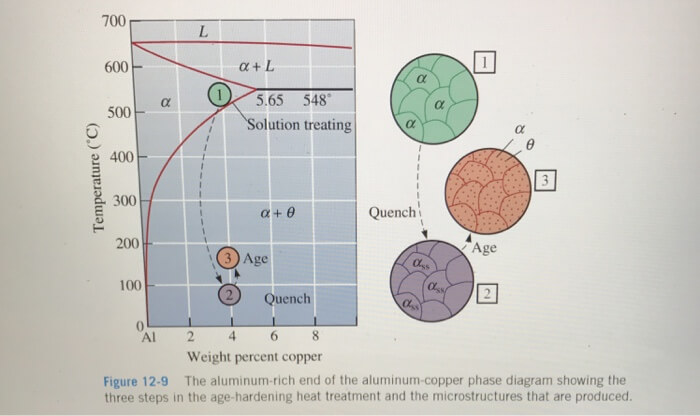

Precipitation hardening is accomplished through three phases:

Each of these phases is touched upon below.

During this phase, precipitates are dissolved, reducing any segregation that may already be present within the alloy mix.

First, the mixture of alloys (typically nickel, chromium, molybdenum, cobalt, iron, niobium, and tantalum) is heated and then soaked according to a predefined solvus temperature.

After that, the solvent is allowed to cool.

Once the solvent cools down enough to turn into a homogeneous solid solution, it is ready for the second phase.

The quenching phase is characterized by rapid cooling, which does not allow any precipitates to form on the nucleation sites of the newly formed supersaturated solid solution.

The third and final stage of precipitation hardening (aging) strengthens the lattice of the solid solution by heating the metal below the solvus temperature.

This creates precipitates, while simultaneously inhibiting dislocation movements from occurring.

While Hastelloy is formed solely through the solid solution strengthening process, many of the Inconel class of alloys can be formed by using either solid solution strengthening, precipitation hardening, or both, amplifying the benefits of each process.

Inconel and Hastelloy both have nickel as their foundation, as mentioned earlier. However, that does not mean they are identical in their total composition, or their performance in different environments.

For instance, Hastelloy is more suitable for acidic environments, while Inconel is better for oxidizing environments.

This is because Hastelloy has a higher molybdenum content, which supplies more resistance in non-oxidizing and acidic environments. On the other hand, higher chromium content in Inconel alloys offers more support in oxidizing environments.

Hastelloy’s specific chemical combination and quantity of nickel, chromium, and molybdenum are specifically designed to reduce media corrosion, which helps in lowering the high costs of equipment repair, replacement, deterioration, performance, and downtime.

Inconel alloys that contain more iron than nickel tend to work well in lower temperature environments and settings, while maintaining their heat resistance in medium to slightly high-temperature surroundings.

Furthermore, when titanium, aluminum, and niobium are added to Inconel alloys during the precipitation hardening process, their mechanical strength and corrosion resistance are enhanced to a large degree.

As can be seen from the tables, Inconel alloys and Hastelloy alloys share many similar elements but also differ in the quantity of those elements plus the addition or subtraction of others.

This ultimately gives each class of alloys a slight advantage or disadvantage in different environments.

In the next section, we shall look at which industries use these superalloys and which applications they use them for.

The different compositions of the two superalloys make them suited for applications in varying industries, although there remains some overlap when it comes to their uses.

Let’s first take a look at which industries Inconel is most widely used in and which applications they are best suited for.

Inconel is commonly used for numerous applications within the following five industries:

The specific applications within these industries that utilize Inconel alloys are as follows.

| Aerospace | Rocket Boosters (studs & nuts) Rocket Skins Thrust Chambers Engine Manifolds Engine Combustion Chambers (3D Printing) |

| Automotive | Battery Pack (Tesla Cars) Turbine Wheels Exhaust Valves Exhaust Manifolds Exhaust Systems |

| Oil & Gas | Chemical Processing Equipment Drilling Tools Flare Blooms Valves |

| Marine | Propeller Blades Wire Ropes Propulsion Motors Sheathing (communication cables) Hangers Platform Risers High-Strength Fasteners Down-Hole Equipment |

| Waste Processing | Storage Tanks Nuclear Waste Management Systems |

Inconel alloys exhibit a strong resistance towards high temperatures and high pressure.

They are also highly-corrosive resistant, which makes them a perfect manufacturing material for the above applications especially since they are lightweight, and don’t weigh down and slow down functionality.

Now, let’s take a look at the industrial applications that utilize Hastelloy as their primary manufacturing material.

Hastelloy alloys are widely used in the following industries:

The specific industrial applications that are comprised primarily of Hastelloy include:

| Aerospace | Rings Seals Cases Nozzles Shrouds Diffusers Manifolds Flame Holders Fuel Systems Exhaust Ducts & Nozzles Afterburners Tail Cones |

| Oil & Gas | Oil Wells Gas Wells |

| Chemical | Piping Systems Pressure Vessels Heat Exchangers Reactor Equipment (various) Columns |

| Power Generation | Gas Turbine Parts (combustors & exhausts) Coal-Powered Plant Systems |

| Pharmaceutical | Buffer Solutions Active Pharmaceutical Ingredients (API) |

Hastelloy’s unique formulation gives it the ability to maintain its mechanical properties in high temperatures—within 90 percent of its meeting point—and gives it a highly-corrosive resistant surface that can withstand sulfuric acid and other oxidizing chemicals.

These features have not only made this superalloy an ideal building material for the applications listed above.

They’re also indispensable for creating many critical components within nuclear submarines, industrial heating equipment and waste processing systems.

Finally, they find their application in mineral processing equipment, and mining systems and applications.

In short, Hastelloy is a very versatile material.

Inconel and Hastelloy are both nickel-based superalloys and share similar properties. They are a good fit for applications that need to withstand high-heat, high-pressure, and highly-corrosive substances.

However, they also differ in many regards.

Inconel’s unique composition gives it more properties that are suitable for oxidizing environments, while Hatelloy’s fares better in acidic environments.

Since they do share many similarities in their processing, composition, and uses, it can be quite difficult to tell which one is best suited for a particular system, component, or application.

This is why we suggest consulting with your custom metal parts manufacturer before choosing, to be sure you get the right alloy for your project.

For further information about the alloys we work with, contact us via the convenient website form or submit a request for quote directly.

We welcome your inquiries.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote