Hastelloy is one of the main manufacturing materials used in industries that operate in highly corrosive environments such as petrochemistry, oil and gas, and marine industries.

However, there are many different grades of Hastelloy, which makes their selection very tricky if you are not familiar with the specific properties each one exhibits.

To make this selection process easier, the following sections will cover some of the most important aspects of this specific nickel-based alloy.

We’ll describe how it is made, go over the different types of grades that are available, and provide some basic manufacturing information, including its benefits, applications, and properties.

Hastelloy is a nickel-based metal that is alloyed with chromium and molybdenum to increase specific properties such as corrosion resistance.

The combination of nickel, molybdenum, and chromium enhances resistance to corrosion and oxidation, as well as workability, ductility, and formability (easy fabrication).

Hastelloy is primarily made from nickel which has so-called coherent twin boundaries, special boundaries which prevent corrosive damage from occurring on the surface.

The material also contains molybdenum, which has even more corrosion protection properties, as well as chromium, which adds an extra layer of oxidation resistance to the mix.

Aside from nickel, chromium, and molybdenum, this superalloy also contains varying degrees of other elements that enhance its high-stress and high-temperature resistant qualities.

These additional elements include:

Hastelloy’s chemical composition gives it an added anti-corrosion advantage over other nickel-based, corrosion-resistant alloys like Inconel, especially when it comes to surface damage like cracking and pitting.

The combination of nickel, chromium, and molybdenum, along with some of the other metal and non-metal elements mentioned above, allows Hastelloy to maintain its physical and mechanical properties in moderate to extreme conditions, including corrosive and erosive ones.

Hastelloy can keep its structural integrity in high temperatures ranging from 2300- 2470°F, i.e., 1260-1,355 °C) and under high-stress conditions (tensile strength: 601.2 MPa, 87200 psi, and high yield strength: 204.8 MPa, 29700 psi).

Aside from its unique composition and outstanding chemical and mechanical properties, its special formulation also gives it a very good price-to-performance ratio making it both an efficient and cost-effective manufacturing material for applications operating in harsh environments.

The different elements in Hastelloy are typically combined while in a hot liquid state (molten metal) before cooling and solidifying.

The prime ingredients in Hastelloy (nickel, chromium, and molybdenum) are heated first, before the other metallic and non-metallic elements are added to the molten mix to ensure strong corrosion resistance.

The general process for creating Hastelloy typically involves six steps which include:

It should be noted, however, that the different grades of Hastelloy contain different percentages of metal and non-metal elements, but the primary transition metal will always be nickel as it is the foundation for the superalloy’s extreme corrosion-resistant properties as well as its outstanding manufacturing qualities like formidability, workability, and ductility.

Even though the Hastelloy creation process will typically follow the general steps outlined above, the composition and specific properties of each type will vary to some degree, making each one more suitable for certain applications.

The different grades of Hastelloy alloys will be the subject of the next section.

Different grades of Hastelloy can be produced depending on the chemical composition and percentage of specific types of metals and non-metals combined.

The main grades include:

A brief description of the different compositions, properties, and applications for the most popular types of Hastelloy in each grade is given below.

In general, Hastelloy B has excellent corrosion resistance against hydrogen chloride gas and hydrochloric acid.

It also maintains a high degree of strength in high temperatures of up to 2003°F (1095 °C), making it a good manufacturing material for industrial equipment like rockets and combustion engines.

Hastelloy B-2 can withstand reducing chemicals and exhibits excellent resistance to intergranular corrosion.

This type is not affected by reducing chemicals and intergranular corrosion, making it a very good choice for equipment that operates in sulfuric and hydrochloric acid environments.

Finally, Hastelloy B-3 contains around 25 to 30% molybdenum, which gives it additional properties like atmospheric pressure resistance and extra resistance to many forms of corrosive acids.

It has one of the lowest corrosion rates of all B-grade Hastelloys, with a rate of .5 mm per year.

Generally, Hastelloy C has good resistance to all forms of corrosion, as well as resistance to radiation damage.

Hastelloy C-4 displays a wide array of beneficial properties, including corrosion resistance (oxidation and reduction), high-temperature resistance, thermal stability, and toughness.

Hastelloy C-22 is primarily composed of nickel, chromium, molybdenum, and tungsten, giving it good all-round resistance to all forms of corrosion, including pitting, crevice, and stress corrosions. It also has a high resistance to aqueous corrosions like nitric acid and wet chlorine.

Hastelloy C-276 contains good corrosion resistance to oxidizing corrosion, reducing regular, stress, and localized corrosion.

It also has adequate resistance to many harmful corrosive chemicals and elements like acid, chlorine, and seawater.

Hastelloy C-2000 is composed of mostly nickel (55%), with the remaining elements including chromium, copper, carbon, and silicon.

Its special formulation helps increase chemical and mechanical properties such as corrosion resistance, high-temperature resistance, as well as tensile and yield strength.

To begin with, Hastelloy G-3 has one of the highest numbers of corrosion-resistant properties among all Hastelloy alloys, including oxidation resistance, atmospheric corrosion resistance, stress corrosion resistance, pitting corrosion resistance, and crevice corrosion resistance.

Hastelloy G-30 is mainly composed of nickel and chromium and exhibits higher corrosion resistance than other anti-corrosive iron and nickel-based alloys.

It can also withstand extremely corrosive acids like phosphoric and oxidizing acids.

Moreover, it has the added feature of being able to prevent welding damage and heat treatment process damage, which occur during the manufacturing process.

Hastelloy G-35 has excellent resistance to pitting and crevice corrosion, as well as certain types of stress corrosions such as those caused by harmful agents like chloride ions.

It also exhibits an adequate amount of resistance against oxidation and reducing agents.

Hastelloy X is similar to many of the other Hastelloy grades in that it is primarily composed of nickel, molybdenum, and chromium, with the difference being additional amounts of tungsten and cobalt.

They give it higher oxidation resistance in high temperatures of over 2,000 °F (1090 °C).

This type of Hastelloy can also maintain its structural integrity and functionality in neutral, reducing, nitriding, and carbonization environments.

All grades of Hastelloy hold many advantages for industrial manufacturing.

High chromium and molybdenum content, along with its primary transition metal (nickel), gives Hastelloy alloys good corrosion resistance against many corrosive chemicals, including oxidizing and non-oxidizing acids, as well as pitting and crevice corrosion.

Due to other metal and non-metal elements being added to its basic composition, Hastelloy’s corrosion-resistant properties can also multiply.

Some forms of Hastelloy will offer superior corrosive resistance in reducing environments and upon contact with oxidizing agents (salts), which tend to form explosive mixtures when in contact with other oxidizing materials.

Aside from its ability to fend off corrosion damage and mitigate hazardous explosions, Hastelloy offers many other physical, mechanical, and thermal properties such as:

Hastelloy is also one of the only alloys that are resistant to wet chloride gas and chlorine dioxide solutions, which are both highly toxic and flammable.

Since Hastelloy superalloys can be changed to enhance or add beneficial properties that are needed to protect functionality and structure, they can be utilized for manufacturing many applications working in moderate to severe environments and atmospheres.

These applications will be discussed in detail in the following section.

Hastelloy has required properties for any application running in moderate to severe environments, such as those found in the chemical and petrochemical industries.

Any application or equipment working in an industry that is subject to corrosive agents, high temperatures, and heavy load stresses would benefit tremendously from the use of Hastelloy in its production.

Aside from the petrochemical and chemical industries, Hastelloy is also widely used in the following industries:

The following list is a sample of the most common applications of Hastelloy, utilized within those industries listed above:

As can be seen from the extensive list above, Hastelloy has a broad range of manufacturing capabilities for applications that need tough and strong structures that can withstand and prevent damage caused by stress, corrosion, and high temperatures.

However, these properties are not the only reason why Hastelloy is used in so many industries and for so many applications.

Its fabrication properties are also highly prized, especially when it comes to the formation of structures and parts.

Perhaps no other fabrication feature is more sought after for industrial applications than weldability.

If Hastelloy could not be welded, then it would be of little use to the industries we listed as using it.

Welded material provides essential strength and support for almost every type of application they utilize

Welding ensures the safe construction, longevity, and functionality of industrial and non-industrial applications and products.

So to answer the initial question presented earlier, yes—all Hastelloy grades can be welded, provided it is done in accordance with safe and proper welding standards.

While there are various welding methods for manufacturing alloys, the ones most conducive to the manufacturing of Hastelloy components include:

A brief description of each is given below:

This welding process uses an electric arc that joins an electrical wire with the material (metal) of choice.

The constant contact between the two produces enough heat to heat the metal and the electrode to its melting point.

During the process, the arc is protected (shielded) from contaminants in the atmosphere with shielding gas.

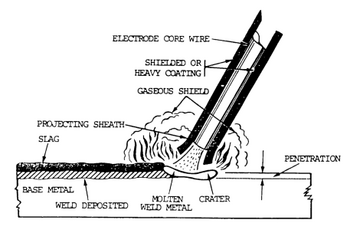

Shielded metal arc welding is similar to the GMAW method but differs in how it shields the electrode (wire arc) from atmospheric contaminants (gasses).

While GMAW uses a gas shield, SMAW relies on flux shielding, which is a material that turns into a gaseous protective layer once the electrode wire and metal have melted.

During SAW, an electrode is constantly fed to the metal to melt it into a workable form.

The most distinguishing feature of this method is its ability to join two different metals together during the weld.

To protect the electrode and metal arc during welding, a blanketing technique is employed, which utilizes a gas flux to cover the molten zone.

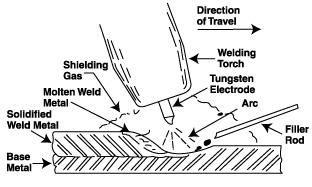

In this process, a tungsten electrode is used to heat and weld the metal. The tungsten electrode is non-consumable and therefore will not melt along with the metal.

The unique characteristic of GTAW is the lack of weld slag which typically occurs with all other welding methods.

The GTAW method uses an inert gas like argon or helium to protect the molten metal from contaminants.

Since Hastelloy has a medium melting point, it can easily be welded using any of the above methods.

This is a great advantage for structures and components made of it, as welded joints ensure higher strength (often higher than the parent material), a smoother look, and the proper joining of two or more metals containing properties that support and enhance one another.

If you need custom metal parts to run in harsh environmental settings, Hastelloy might be the right choice of material.

The different grades of Hastelloy can deal with almost all forms of corrosion caused by all kinds of corrosive materials and environments, including acids, seawater, and oxygen.

Hastelloy also exhibits high-stress resistance and high-temperature resistance, which are usually required in moderate to extreme industrial settings.

Since there are so many grades of Hastelloy, each one with specific qualities that make it a prime candidate for different applications, we recommend contacting a full-service custom metal manufacturer to help you select the Hastelloy grade for your particular project.

Contact BUNTY LLC Today

For further information about the alloys we work with, contact us directly via the convenient website form or request a quote here. We welcome your inquiries.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote