Metal forging is the process of reshaping and forming metal into a desired shape by applying compressive force.

While the process is generally reliable, there are certain defects most forging methods are prone to, like cracking and grain growth.

This article will discuss those common defects, their causes, and ways to address them.

Understanding these issues can help manufacturers identify and prevent them from occurring, thus increasing product quality and efficiency in metal forging and other metallurgical processes.

Unfilled sections in forged parts can lead to significant problems that could even result in the part being discarded.

This issue is often encountered when there is a lack of raw material supplies.

It can also be caused by the implementation of incorrect forging techniques, as well as insufficient heating, and improper die design.

To ensure a successful forging operation, it is important to understand how each of these factors contributes to the occurrence of unfilled sections.

If a die is designed with incorrect dimensions, the proper flow of metal into all areas of the die cavity may be hindered, resulting in incomplete filling or empty cavities.

In other words, poor die design can result in the appearance of unfilled sections in the forging.

Therefore, the geometry or dimensions of the cavities must be accurate and precise if you want the dies to produce quality forgings.

The first step in improving die design is to select the correct material for making them.

This should be done based on both the application requirements and properties such as wear resistance, thermal stability, chemical composition, and mechanical strength.

The second step is ensuring that all components within a die set are designed properly to minimize stresses within each component.

Properly designed dies ensure that the final forgings are free of imperfections.

Unfilled sections can also occur if insufficient heat is applied to the metal before it is shaped.

If the metal isn’t hot enough when it enters the forming die, it won’t flow properly into all of the recesses that make up its shape.

As a result, air pockets or voids will appear within the forged part, weakening its structure and reducing its quality.

To make sure there is enough heat during forging, it’s important to use a reliable source of fuel that can burn hot and long enough to shape the selected metal.

For instance, coal and natural gas are both known for providing consistent and powerful sources of heat.

Additionally, selecting a forge design that allows for the control of the fuel supply will help keep temperatures steady while allowing room for adjustments when necessary.

Finally, using insulating materials such as ceramic pads can also help maintain an even temperature by preventing excessive heat loss during forging.

Improper forging techniques can result in weak points in the finished product, which could potentially lead to unfilled sections.

Common improper forging mistakes include:

Too much pressure applied during forging will also lead to voids, as some parts of the material may be pressed out rather than filled in.

There are many different types of forging, each with its advantages and disadvantages.

Getting acquainted with the available forging methods will help you detect the right technique for the job.

If the correct materials are not available during the forging process, that can also lead to imperfections in the final product.

The most common forging materials are:

In addition to metals, other materials such as fluxes, lubricants, cooling agents, and quenching oils may be necessary to forge particular items.

Figuring out what materials are needed for the project starts by considering what kind of environment the forging will take place in.

Different materials have different levels of corrosion resistance, heat tolerance, and other characteristics that could affect their performance under varying conditions.

The type of tooling used should also fit the forging method to avoid defects like voids and gaps.

With a bit of planning, unfilled sections can be avoided no matter which forging method is chosen.

Cold shuts are defects that appear at the corners of a workpiece and are caused by rapid cooling.

They typically look like small cracks and can be identified by their location, size, and shape.

The rapid cooling that leads to cold shuts is usually caused by inadequate amounts of molten metal present during the forming process.

The insufficient temperature results in a lack of fusion between adjacent pieces which form the corner, thus creating a sharp edge on the surface.

The severity of cold shut defects will depend on many factors, such as weld joint design, welding technique, heat input level, and coolant flow rate.

To prevent cold shuts from occurring, it is important to use low heat inputs during welding and forging operations, as well as ensure proper cooling rates for all welds during forge weldings.

It is also important to increase the die’s fillet radius to avoid cold shuts from occurring.

A fillet is a rounded transition between two intersecting surfaces, like in a mold or die.

Increasing the fillet radius will help improve resistance to wear on the tooling surface over time and increase overall product strength without sacrificing quality or material integrity.

The increase will also aid in preventing residual stresses from causing premature failure during forming operations.

Scale pits are small cracks or holes found on the surface of metals. They are usually caused by improper cleaning or scale formation on forged surfaces.

This type of defect commonly occurs when forging a metal at high temperatures, especially when it is done in an open environment.

In an open environment, oxygen and other elements come into contact with the hot metal while it is being forged.

When oxygen comes into contact with hot metal, dry oxide scale is formed on the surface of the material.

As oxides and other materials are fused to the metal surface during forging, they need to be removed immediately.

Otherwise, they will create weak spots on the metal’s structure and eventually lead to scale pits.

To prevent these scale pits from forming, metal forgers often use protective coatings such as oil or grease during their forging processes.

Additionally, some forgers utilize vacuum furnaces or sealed chambers.

That way, they can count on an oxygen-free working environment that effectively eliminates any oxidation from occurring on their workpieces.

As far as avoiding improper cleaning during forging operations, manufacturers and engineers can use cleaning and removal techniques such as sandblasting to eliminate all traces of scale from the metal’s surface.

Die shift misalignment occurs when two or more dies in a press machine are not correctly aligned relative to each other.

Misalignment can cause an array of issues, ranging from poor-quality products to significant production delays.

It can occur due to physical wear and tear on the machine or improper setup by operators.

The result is that parts are finished off-center or out of tolerance due to the nature of their function.

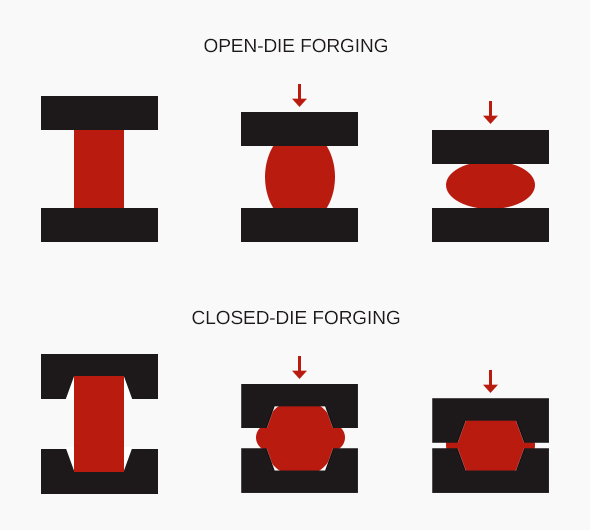

Die shift defects are common both during closed-die forging and open-die forging operations.

To prevent die misalignment from occurring, it is important that both die sets rest on parallel planes and have an equal gap between their faces.

It is also essential to securely fasten them together, so they will stay aligned throughout the entire forging process.

Additionally, using specialized tools such as optical comparators or 3D scanning equipment can help ensure accurate alignment of the dies before each forging cycle.

By taking these precautions, manufacturers can avoid costly inaccuracies in dimensions that result from die misalignment.

Flakes are internal cracks on metal surfaces that can damage the strength of forged metal and reduce its performance.

They appear as layers of thin shavings on the surface of the forged material and are caused by inadequate tempering temperatures during production.

Flakes occur when forged metal cools too quickly.

The most common cause for this defect comes from using improper quenching media, such as water or oil, at temperatures that are too cold.

As a result, the material suffers too much thermal shock, causing it to crack and form flakes instead of uniform pieces with no cracks.

It is important to identify flakes early on, either through visual inspection or ultrasonic testing, to prevent further weakening or potential failure of the metal part.

Maintaining appropriate temperatures during forging and using appropriate tools helps avoid these internal cracks from forming.

The workpiece’s temperature must rise and fall slowly during forging to help keep its grain structure aligned and prevent any cracks or fissures from forming on its surface.

Additionally, cooling should not be abrupt, as this may also cause severe structural damage over time.

Instead, a gradual cooling time throughout the entire forging process is recommended.

Residual stress is defined as the internal stress that remains in a material after it has been subjected to plastic deformation during forging.

Unlike other forms of stress, residual stress, as its name implies, remains present in the material even when external forces that cause it are removed.

When metal undergoes plastic deformation, its crystalline structure will become distorted.

This distortion causes compressive or tensile stresses to form within the material itself.

The presence of residual stress in a workpiece lowers its fatigue resistance.

Since residual stress can cause parts to deform or crack prematurely, they must be managed carefully during forging.

For example, if a forging process results in excessive residual stress levels, then it might be worthwhile to increase cooling times.

Alternatively, additional heat treatments may need to be employed during post-forging operations.

Another way to minimize the impact of residual stress on metal is to make sure that it has been properly conditioned before it enters the forging press.

Conditioning the material beforehand will help minimize any residual stress caused by working at high temperatures or pressures.

Finally, proper maintenance of equipment such as die sets should also be completed regularly.

Die clearances should also be checked with each use, to ensure that everything is running smoothly before the forging process begins and thus reduce any added strain on the metal being formed.

Surface cracking is a defect that occurs when temperatures are too low during the forging process.

This issue can cause significant disruption to production and lead to expensive post-forging treatments or even scrap.

The most common cause of surface cracking is incorrect heating of the metal before it’s formed.

When heated too quickly or unevenly, different parts of the workpiece become hotter than other areas, causing stress that leads to cracking when it cools down.

Inadequate tool maintenance can also result in surface cracks due to a poor fit between the die and hammer components, especially during hot forging.

Although residual stress defects and surface cracking may appear to be similar, they are two distinct concepts.

As indicated earlier, residual stress occurs when objects or materials are exposed to any form of external force that creates a strain within the material.

On the other hand, surface cracking occurs when an object is subjected to extreme stresses or temperatures, causing it to break down into smaller fragments.

To prevent surface cracking from occurring, metallurgists and engineers need to understand how different factors such as temperature, strain rate, and material composition affect forged parts.

Proper temperature control is one of the most essential factors in reducing the risk of surface cracking.

Working at a higher temperature than usual will almost always help mitigate surface cracking as it helps ensure that the temperature remains consistent throughout the entire forging process.

Grain growth defects appear when the grain structure of a workpiece fails to align with its shape, resulting in an uneven distribution of grains across the surface.

This problem can be caused by several factors, including high temperatures, slow cooling rates, and inadequate fluxing agents.

One of the main causes of improper grain growth during forging and casting is poor die design, which we discussed earlier.

The effects of grain growth are significant and may include changes to properties such as ductility and strength.

It can even lead to total failure of the component.

To prevent this defect from occurring, proper control measures should be taken during the casting or forging process.

These measures include using higher pouring temperatures, slower cooling rates, and appropriate fluxing agents, which reduce oxidation on the molten metal’s surface.

It is also of utmost importance to maintain a mold design that is aligned with the shape and size of the metal.

This secures optimal grain size control and alignment with component geometry.

Inadequate penetration during forging occurs when the metal does not reach high enough temperatures.

If a forge is not hot enough, it will not be able to penetrate through all parts of the metal being worked on, weakening it significantly.

Improper forging penetration can also happen when hammer blows are too weak or too quick.

With soft and fast blows, the metal won’t fully occupy a die, so it will undergo no significant change in its internal structure.

For the forging process to be correctly carried out, the hammer needs to be struck with sufficient energy and at a consistent rate that is suitable for the size of the workpiece.

If this is not done, major issues such as inadequate strength, surface cracks, and inclusions can occur.

When assessing an improper forging penetration, several indicators can help distinguish it from other defects.

These include visible dimples on the surface of the part as well as depressions beneath various locations on the part’s surface.

To make sure that forging has been properly undertaken, visual inspections should always be conducted during the process.

In addition, controlling and calibrating the hydraulic system of the press will make sure correct alignment and lubrication of the die have been achieved.

Finally, using the right forging temperatures suitable for the chosen metal will help limit insufficient penetration and any defects caused by it.

Understanding common defects in metal manufacturing is essential to finding the right materials and processes to create safe, functional, and reliable products.

By learning more about the different types of forging defects and how they are caused, manufacturers can take steps to reduce the risk of such issues from occurring.

Understanding the defects listed in this guide can help metal manufacturers uncover potential flaws and therefore help them save money over time.

Waste from scrapped materials will be decreased, and going through costly re-tooling processes will be avoided.

Detecting forging flaws earlier can also lead to faster production times since fewer steps will be needed for completion.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote