Extrusion casting (a.k.a. squeeze casting, liquid forging) is a unique and relatively new manufacturing process.

The process uses high temperature and air pressure to reshape molten metal into usable components and parts for a variety of industrial applications.

Metal casts created by the extrusion casting process are used in many markets because of their strength, durability, and lightweight properties.

In the following sections, we will discuss the extrusion casting process in detail.

We will highlight the significance of metal extrusion and describe how it compares to other metal manufacturing processes like die casting and forging.

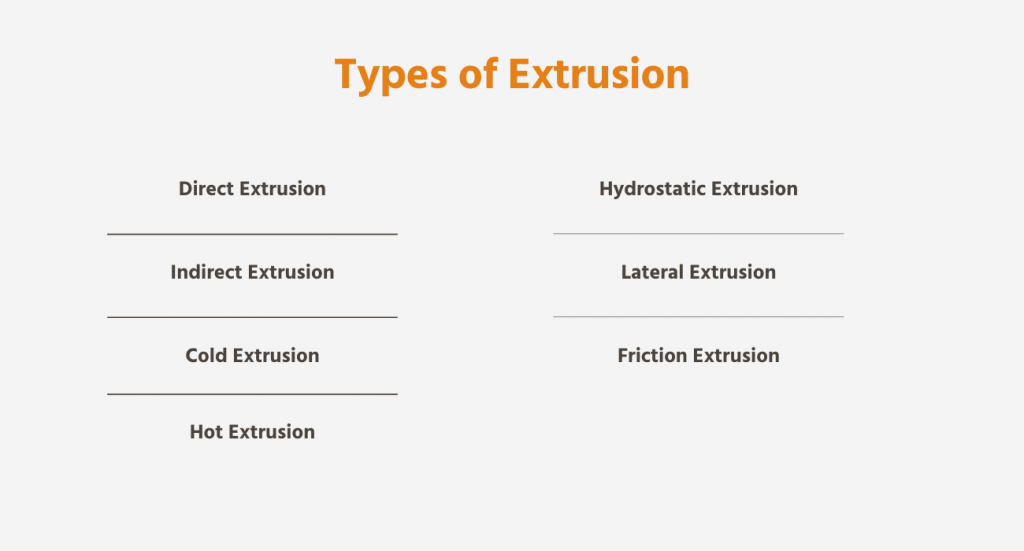

Finally, we will go over the different types of extrusions along with their practical applications within industrial settings.

Extrusion casting is a metal matrix manufacturing process that combines both casting and forging methods.

This combination creates products with desirable mechanical properties, useful in a number of industries.

Combining forging and casting methods shortens the manufacturing process, saves energy, eliminates material waste, and increases flexibility and quality in mechanical parts.

The ability to reshape and mold aluminum alloys with external pressure is particularly interesting.

It helps prevent shrinkage porosity, thus creating a more durable mechanical part that will not crack or break under stress.

The extrusion process is relatively simple and can be summed up in two steps:

First, molten metal is poured into the bottom half of a preheated die.

Then, the upper half of the die closes off the bottom half, and pressure is applied to solidify the cast.

While its unique ability to work with aluminum alloys sets it apart from other casting and forging methods, it can work equally well with ferrous metals (alloy steel, carbon steel, cast iron, wrought iron), non-ferrous metals (copper, lead, zinc, tin), and composite materials like kevlar.

The term “extrusion” refers to a process in which cross-sectional products are created.

The extrusion process can create complex cross-sections using brittle material.

Some examples of products that are made through the extrusion process include various tubes, pipes, battery cases, and aluminum cans, among others.

Metal extrusion is a relatively old manufacturing method first introduced by Joseph Bramah, the inventor and locksmith, in 1779.

In metal extrusion, either hot or cold metal is forced through a cavity filled with die. During the solidification process, it takes the shape of the die as it passes through.

The reason the metal can take the shape of the die is that high temperatures and pressure are forced upon it as it enters the die cavity.

There are many benefits to using metal extrusion, some of which have been given below:

Metal extrusion is used in extrusion casting to shape all forms of industrial metals, including steel, copper, zinc, and titanium.

Extrusion casting is often considered a variant of die casting as the two share similar metal manufacturing techniques and methods to mold molten metal into solidified mechanical parts.

However, some distinct features separate the two.

Although both methods use molten metal and die to form mechanical components, extrusion casting includes a slower metal velocity at the gate.

In other words, molten metal is poured into the die more slowly, to avoid shrinkage and gas porosity

Another major difference between the two methods is the die design.

In extrusion casting, the die gates (the cross-sectional area designed to direct metal into the die) are thicker and also include a larger biscuit (the area where excess metal is kept) and a large shot (piston used to inject molten metal into the die cavity).

These two enhanced designs make sure that the gates do not freeze and that shrinkage is minimized during the solidification process.

In summary, extrusion casting holds several advantages over traditional die-casting.

It nearly eliminates shrinkage and gas porosity, as well as lessens turbulence during the filling process, which, if not kept in check, can lead to large gaps and voids in the final cast.

The main similarity between extrusion casting and traditional forging is that both processes take place inside special forging equipment, usually a hydraulic forging press.

Forging presses are less expensive and have a quicker cycle time than other metal manufacturing machines.

However, since extrusion casting is a hybrid of both forging and die casting methodologies it offers more advantages than the forging process can provide alone.

One of the main differences between the two manufacturing processes is in the items that are heated during manufacturing.

In metal forging, the work material is heated, while in extrusion casting, it is metal that is heated until it is liquified.

Due to this difference, extrusion casting tools are less expensive than those used in forging, as they have to withstand much less heat during the manufacturing cycle and therefore do not have to be replaced as often.

Some of the major advantages of extrusion casting over traditional forging include:

Extrusion casting can also produce tough casts.

As a result, it combines the malleability of die-cast components with the tough surface structure commonly attributed to forged parts resulting in products that are suitable for many industrial settings and applications.

The basic extrusion process always involves forcing or pushing metal through a pre-shaped die to create objects with different shapes and patterns.

However, there are different ways of completing this task depending on the temperature used, the method of pressure, and the extrusion flow.

The seven most common types of extrusion processes have been listed and briefly described below.

This is the most common form of extrusion.

Direct extrusion utilizes mechanical or hydraulic pressure to push metal inside a press cavity container through the die.

The die, located at the end of a hydraulic ram press, moves towards a billet (an unshaped bar of metal, usually aluminum) to push it through the die.

This process uses less power than the direct method. This is because the billet does not have to move, thus creating less friction within the cavity.

Metal, in the form of slugs, is forced through the die at room temperature and then pressurized to create a new shape.

Metal is heated at high temperatures (650—1,300 degrees Fahrenheit) until it becomes molten or liquified.

The molten melt is then forced through the die, where pressurization takes place to reshape the melt into the desired form.

The chamber size is reduced and filled with hydraulic fluid to push the metal through the die.

The container is placed in a vertical position so the metal can be easily pushed into the die located on the side of the cavity.

Heat is produced by the automatic rotation and friction of dies located at the die entry point. This heating mechanism makes it easier for the metal to pass through the die.

Extrusion casting materials are one of the most popular choices for a variety of industrial applications.

Some of the more popular examples include:

We have provided a short overview of each of these applications below.

The range of extrusion cast parts used for both architectural and construction purposes is vast.

All of the following are made through the extrusion process:

The reason extrusion casting is one of the most beneficial manufacturing options for many architectural and construction applications is due to the lightweight yet durable products it can produce.

Extruded metal components, especially extruded aluminum, are used in several electrical systems as they are good conductors of electricity.

Some of the more common extruded electrical components and parts include busbars, LED fixtures, and solar panel support structures.

Not only are extruded electrical components good conductors, but they are typically lightweight and corrosion-resistant.

This makes them an ideal addition to a wide range of electrical equipment.

Extruded aluminum is the most popular material used in industrial equipment today.

It is lightweight and durable, easy to work with (cut and drill), and relatively inexpensive to produce when compared with other metals and manufacturing processes.

Some examples of extruded aluminum materials used in industrial equipment include inspection tables, workbenches, machine-guarding frames, and carts.

Extruded aluminum can also be extended, which means that industrial equipment made with this material can be adjusted and modified as needed.

Metal extrusions continue to make an important contribution to the automotive and aerospace industries.

They help increase fuel efficiency and limit fuel emissions due to their lightweight structures.

In addition to a host of airplane and aerospace components, the following are all produced via extrusion casting:

Aside from their practical applications in the automotive and aerospace and aircraft industries, extruded aluminum alloys are also prized for their decorative properties, specifically their corrosion-free, rust-resistant nature.

Extrusion casting offers many benefits for those who require metal manufacturing.

Metal extrusion is a low-cost, high-volume metal manufacturing process that can use a wide range of metals to create lightweight, durable, and complex components with good mechanical properties.

Since it combines both casting and forging methods, it offers all the advantages of each process while minimizing drawbacks.

As there are many options to choose from when it comes to extrusion casting, it is best to consult with your metal manufacturer before beginning any extrusion project.

A professional will guide you as to which one will best serve your needs and fulfill your manufacturing purposes.

For further information about our extrusion casting service and other capabilities, please contact us directly via the convenient website form or request a quote here. We welcome your inquiries.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote