Among the multitude of techniques available for manufacturing custom metal parts, die casting and sand casting are two of the most prominent.

Although they are both extremely useful for manufacturing metal components, the two methods differ in many ways.

On top of that, selecting the appropriate casting method can significantly impact product quality, production efficiency, and overall cost-effectiveness.

That is why, in this article, we are going to discuss the key differences between these two methods.

Equipped with this information, you will be able to decide which process is the right choice to deliver the metal parts that meet your standards.

Die casting is used to produce a wide range of metal parts with precision and consistency.

The die casting process involves injecting molten metal (e.g. aluminum, zinc, and magnesium) into a steel mold cavity under high pressure.

The pressure that is applied during die casting forces the metal to conform to the intricate details of the mold, resulting in accurately shaped components with fine surface finishes.

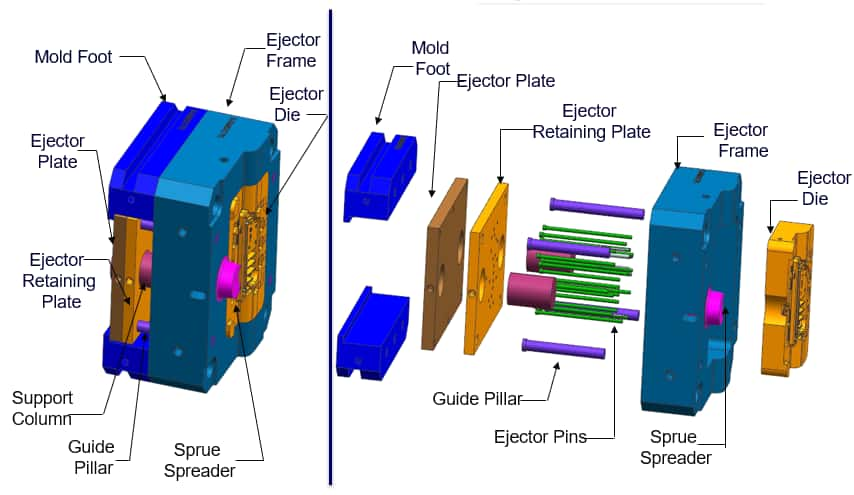

The molds (dies) used in this method are typically constructed from hardened steel and consist of two halves that are precisely machined to form the desired part shape.

Die-casting molds are mounted within a specialized die-casting machine, which securely clamps them together during the casting process.

This casting method offers several notable advantages to manufacturers and businesses looking for custom metal components.

These include:

| High Precision | Die casting enables the production of complex shapes and tight tolerances, which is ideal for creating components with intricate features. |

| Rapid Production | The high-speed nature of die casting allows for the production of large volumes of parts in a relatively short amount of time. |

| Consistency | Due to the use of precise molds and controlled casting conditions, die casting can yield consistent results, ensuring uniformity across all produced parts. |

| Excellent Surface Finish | Die-cast parts typically exhibit smooth surface finishes, which helps reduce the need for additional machining or finishing operations (i.e. lowers costs). |

Today, die casting stands as one of the preferred methods for manufacturing metal parts across the automotive, aerospace, electronics, and consumer goods industries.

Its combination of precision, efficiency, and versatility makes it a good solution for meeting the demanding requirements of modern manufacturing within these industries.

Sand casting is one of the oldest and most traditional methods for casting metal parts—a testament to its effectiveness in real-world applications.

The sand casting process relies on the use of sand as the primary molding material, making it especially cost-effective for producing metal components, ranging from small intricate parts to large industrial pieces.

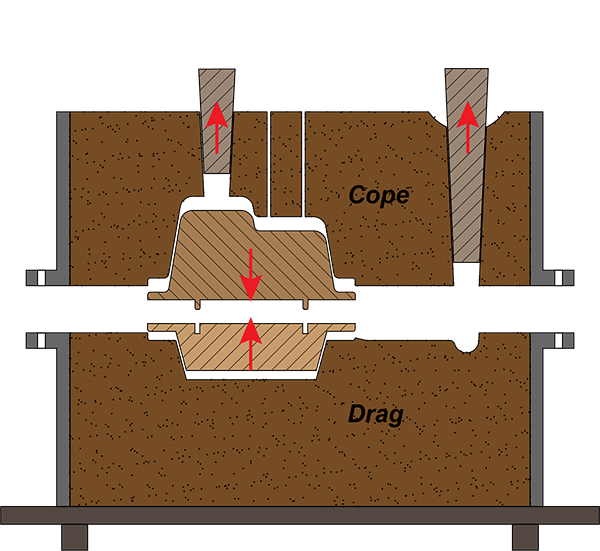

Sand casting uses a pattern or replica of the desired part that is either created from wood, metal, or plastic.

It is then placed within a two-part mold made of sand: the mold consists of a cope (upper half) and a drag (lower half), which are carefully packed around the pattern to create the mold cavity.

Once the mold is prepared, it is separated and the pattern is removed, leaving behind a cavity in the sand corresponding to the shape of the desired part.

Sand casting often requires additional finishing processes such as grinding or machining to achieve the desired surface finish and dimensional accuracy.

The benefits this process offers include:

| Versatility | Sand casting can accommodate a wide range of part sizes and shapes. |

| Low Tooling Costs | The tooling costs for sand casting are relatively low, making it a very cost-effective option for prototypes and low-volume production. |

| Adaptability | Sand casting can utilize various types of sand, binders, and additives to achieve specific properties such as strength, permeability, and surface finish. |

| Complex Geometries | Sand casting can accommodate intricate part geometries and internal features, making it suitable for producing parts with complex designs. |

Despite the above advantages, sand casting also has some limitations when compared to other manufacturing methods (e.g. lower dimensional accuracy and the need for additional finishing operations).

However, its versatility, cost-effectiveness, and ability to produce large, complex parts make it a preferred choice for many applications, particularly in industries that require such parts as those found in the automotive, aerospace, and construction industries.

As can be ascertained from the two previous sections, die casting and sand casting vary significantly in their processes, materials, and capabilities.

In this regard, comparing these two techniques side by side will give a better understanding as to which one would be most conducive for a given metal parts project.

Materials Used for Molds

Die casting employs durable steel molds, known as dies, which are precision machined to form the desired part shape.

These dies are reusable and can withstand high temperatures and pressures associated with the die-casting process.

Sand casting, on the other hand, utilizes expendable molds made from sand, which are typically mixed with binders to hold their shape.

These molds are relatively inexpensive and easy to produce, but they can only be used for a single casting operation before being discarded.

Complexity of the Parts

Die casting excels in producing complex parts with intricate geometries and fine details.

The high-pressure injection of molten metal into the precision molds allows for the replication of intricate features with high accuracy.

While sand casting can accommodate a wide range of part sizes and shapes, it is generally more suited for simpler designs and larger components.

Complex geometries may be challenging to achieve with sand casting due to limitations in mold intricacy and dimensional accuracy.

Wall Thickness

Die casting enables the production of parts with relatively thin wall thicknesses, which helps maintain uniformity and structural integrity among cast parts.

This capability is especially advantageous for lightweight components requiring precise dimensions.

On the other hand, sand casting tends to produce parts with thicker wall sections due to the limitations of mold design and the inherent properties of the sand molds.

Thicker walls can provide more strength and durability, which is crucial for parts that will be subjected to high stress or wear.

Production Volume

While die casting is well-suited for high-volume production runs thanks to its rapid cycle times and efficient material utilization, sand casting is more conducive to low to medium-volume production runs.

Therefore, the die casting process is ideal for mass-production applications whereas the sand casting process tends to be slower and less automated compared to die casting.

Surface Finish

Finally, the die-cast parts typically exhibit excellent surface finishes with minimal imperfections, therefore no additional finishing processes are usually required.

This is not the case for sand-cast parts, as they may exhibit rougher surface finishes due to the texture of the sand molds.

Additional finishing operations, such as grinding or sandblasting, are required to achieve the desired surface quality when employing sand casting.

As can be seen from the above comparison, die casting and sand casting offer distinct advantages and are suited for different applications based on factors such as part complexity, production volume, surface finish requirements, and material properties.

Now, that you understand these key differences, you are in a better position to make an informed decision as to which casting method is most appropriate for your specific manufacturing needs.

Selecting the appropriate casting process hinges on the various factors that were touched upon in the previous comparisons.

Simply stated, which method to choose will depend on which factor(s) are most important to a given manufacturing project.

In that regard, let’s take a look at which one would be the best choice given each specific manufacturing need.

Die casting is the preferred option for producing intricate parts with complex geometries and fine details.

So, its ability to replicate precise features with high accuracy makes die casting the suitable choice for applications where intricate designs are essential.

Furthermore, die casting excels in producing parts with thin wall sections while maintaining structural integrity.

This capability is advantageous for lightweight components requiring precise dimensions and consistent wall thicknesses.

And if you’re planning high-volume production runs, die casting is, once again, a great choice due to its rapid cycle times, efficient material utilization, and scalability.

On top of that, it offers consistency and repeatability, making it ideal for mass-production applications.

Lastly, if you’re looking for a casting method that requires little to no additional finishing processes, die casting is a good option to consider.

This is because die-cast parts typically exhibit excellent surface finishes with minimal imperfections.

Sand casting, on the other hand, is preferred when working with large, irregularly shaped parts or when producing prototypes and low to medium-volume production runs.

Its expendable sand molds are relatively inexpensive and easy to produce, making it cost-effective for small-scale operations.

However, while sand casting can accommodate a wide range of part sizes and shapes, it is generally more suited for simpler designs and larger components.

Additionally, sand casting tends to produce parts with thicker wall sections, making it a good choice for applications that need a stronger and more durable structure.

In summary, die casting is the preferred choice for high-volume production of complex parts requiring thin wall sections and excellent surface finishes.

On the other hand, sand casting would be a more suitable option for producing large, irregularly shaped parts or for low to medium-volume production runs where cost-effectiveness and versatility are prioritized.

The choice between die casting and sand casting holds significant implications for product quality, production efficiency, and cost-effectiveness.

Understanding the key differences between these two casting methods is paramount for businesses seeking to optimize their manufacturing processes and achieve the desired outcomes.

Since many factors can influence the outcome of both casting processes, it is advised to consult a custom metal parts manufacturer with expertise in both methods to help assess the specific needs of your project and determine the most suitable method for it.

By leveraging the knowledge and experience of professionals in the field, you can make better decisions that can help optimize manufacturing efficiency, minimize costs, and ensure the highest quality metal parts for your applications.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote