When extreme heat, pressure, and corrosion are part of daily operations, ordinary metals just won’t cut it.

That’s why leading businesses in aerospace, energy, marine, and more turn to Inconel—forged to perform in the toughest conditions.

At Bunty LLC, we specialize in custom Inconel forging services designed for durability, precision, and reliability.

If your next project demands high-performance metal parts that don’t fail under pressure, you’re in the right place.

Inconel is a nickel-based superalloy known for doing what other metals can’t: maintain strength, resist corrosion, and perform under extreme heat.

These properties make it the material of choice for industries where failure simply isn’t an option.

Here’s what makes Inconel a top-tier forging material:

One of Inconel’s standout properties is its ability to maintain structural integrity in extreme temperature environments.

Unlike many other metals, Inconel does not easily soften or lose strength under high heat.

Inconel’s heat resistance makes it particularly well-suited for applications in aerospace, power generation, and automotive industries, where components must withstand temperatures ranging from 250°C (482°F) to 1000°C (1832°F) and higher.

This makes it ideal for jet engines, gas turbines, and automotive exhaust systems.

Inconel is highly resistant to oxidation and corrosion.

Its unique chemical composition (mostly nickel, iron, and chromium) allows it to form a stable oxide layer that resists:

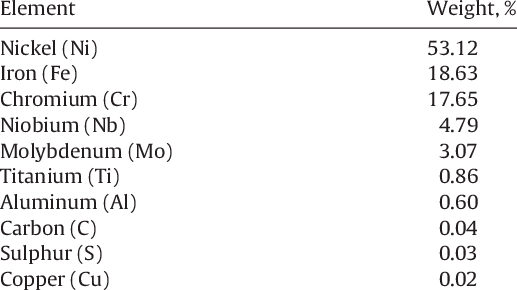

Here is the chemical composition of Inconel 718:

Source: Research Gate

Inconel’s corrosion-resistant properties are ideal for marine, chemical processing, and nuclear energy applications, where exposure to harsh substances is ever-present.

Inconel’s exceptional strength allows it to withstand intense mechanical stress and pressure without compromising its form or function.

Since Inconel can retain its mechanical properties even under extreme loads, it has become a go-to material for applications such as:

Unlike standard stainless steel, which can weaken over time in demanding environments, Inconel remains resilient.

This resilience allows it to reduce maintenance costs and extend the lifespan of critical components.

Inconel is engineered for extremes—high heat, heavy pressure, and harsh environments that would destroy ordinary metals.

At Bunty LLC, we specialize in forging Inconel into custom, high-performance parts that stand up to those extremes.

Our Inconel forging services are built around precision, reliability, and adaptability.

Whether you need heat-resistant turbine components, strong and corrosion-proof marine hardware, or high-stress fasteners for aerospace applications, we tailor every forging process to your exact specifications.

To ensure optimal material properties, we use two key heat treatment processes in our Inconel forging operations:

These treatments help us ensure that our forged Inconel components meet the highest performance standards for strength, durability, and longevity.

Naturally, different applications require different alloys.

That’s why we work with a wide range of Inconel grades, each offering specific benefits:

| Inconel 600 | A versatile, general-purpose alloy with excellent resistance to oxidation and corrosion. Common in aerospace, chemical processing, and furnace components. |

| Inconel 601 | Great for high-temperature environments. Often used in gas turbines, heat exchangers, and exhaust systems. |

| Inconel 625 | Known for exceptional strength and corrosion resistance. Widely used in marine, aerospace, and chemical processing sectors. |

| Inconel 718 | A precipitation-hardened alloy offering high tensile strength, fatigue resistance, and weldability. Ideal for aerospace engines and high-pressure components. |

| Inconel 725 | Combines corrosion resistance with strong mechanical properties. Used in marine hardware, chemical plants, and oil and gas extraction. |

| Inconel X-750 | Known for its high strength and excellent creep resistance at elevated temperatures. It is often used in nuclear reactors, jet engines, and industrial springs. |

| Incoloy 800 | Features good resistance to oxidation and carburization in high-temperature environments. It is frequently applied in heat treating, power generation, and petrochemical industries. |

| Inconel 903 | A specialty alloy known for thermal stability and resistance to stress cracking. Commonly used in advanced aerospace components. |

With this wide selection of grades, we can match the material to your application’s unique demands.

Combined with our proven forging expertise, we deliver Inconel components built for longevity and top-tier performance.

No matter your industry or environment, if your parts need to perform under pressure, Bunty can forge the solution.

At Bunty, we specialize in providing custom Inconel forging services tailored to meet the needs of various industries and applications.

Here’s a look at the key industries we serve and how they use forged Inconel parts:

In aerospace and defense, components must endure intense heat, friction, and stress.

Our Inconel parts are built for just that.

From gas turbines to nuclear facilities, energy systems need materials that won’t fail under high heat or prolonged stress.

The oil and gas industry pushes materials to their limits—downhole, offshore, and everywhere in between.

Inconel holds up where others can’t.

Harsh chemicals, rapid thermal changes, and long operational hours are common in chemical plants.

Inconel delivers durability and resistance.

Inconel is also used in specialized medical applications where precision, strength, and resistance to sterilization are essential.

Could your business benefit from Inconel forging?

If you operate in any of these industries—or anywhere components are exposed to heat, pressure, or corrosion—then yes.

Inconel forging is likely a smart, long-term investment.

At Bunty, we combine deep material expertise with advanced forging techniques to deliver custom Inconel parts that meet your exact requirements.

Strong. Precise. Built to last.

When it comes to sourcing custom Inconel-forged components, choosing the right manufacturing partner is critical—and that’s exactly where Bunty LLC delivers.

With decades of experience and a proven reputation for quality, we specialize in forging Inconel parts engineered for strength, reliability, and performance under the toughest conditions.

Our team combines deep materials expertise with precision manufacturing to produce components that meet exact project requirements, whether they’re exposed to extreme heat, corrosive environments, or constant mechanical stress.

At the core of our operations is a modern manufacturing setup supported by highly skilled technicians and advanced equipment.

Source: Bunty LLC

Every component we forge is produced to tight tolerances and exacting specs.

Take, for instance, a batch of Inconel 718 parts for a jet engine.

Our team ensures each one is shaped, heat-treated, and finished to deliver the fatigue resistance and mechanical strength needed in aerospace environments.

We also operate on a global scale.

With production capabilities in both the U.S. and Asia, we offer faster lead times, competitive pricing, and the flexibility to adapt to your schedule, wherever you’re located.

Source: Bunty LLC

If a chemical plant needs Inconel 625 components for an urgent upgrade, we can quickly coordinate production and delivery across continents, helping minimize operational downtime.

Quality is at the heart of everything we do.

Among other certifications, we hold:

Every part we forge undergoes rigorous testing, from non-destructive inspections to material traceability and performance validation, ensuring it not only meets, but often exceeds, expectations.

Source: Bunty LLC

Choosing Bunty means gaining a manufacturing partner with the expertise, equipment, and global reach to support your most demanding projects.

Whether you’re in aerospace, energy, medical, or chemical processing, we deliver Inconel components that perform under pressure—and help your business stay ahead of the competition.

When your components need to withstand extreme heat, pressure, and corrosion, few materials deliver like Inconel.

And when precision, quality, and durability are non-negotiable, Bunty LLC is the partner you can count on.

With decades of experience, advanced forging techniques, an extensive selection of Inconel alloys, and strict compliance with global quality standards, we consistently deliver custom-forged Inconel parts built to perform—every time.

Ready to move forward?

Contact BUNTY Today

Get in touch with Bunty LLC today to explore how our Inconel forging expertise can power your next project with strength, precision, and total reliability.

From a contract manufacturing firm, BuntyLLC evolved into a full service custom machined, forged and cast metal parts fabrication enterprise. We supply global solutions from our headquarters in Greenville, South Carolina.

Get A Quote