Metal casting is one of the oldest manufacturing methods that continues to be popular largely due to its broad range of applications in many industries spanning from automotive to aerospace and jewelry to medical devices.

However, just because it happens to be an ancient manufacturing technique doesn’t mean the method hasn’t evolved throughout its illustrious history

New manufacturing challenges and opportunities continue to expand the efficiency and effectiveness of this process, especially when it comes to the production of custom metal parts.

Therefore, we delve into four trends that are currently transforming metal casting, outlining how they benefit the process and the advantages they can bring to businesses that rely on this method for the production of metal products and components.

Businesses that are aware of and follow these trends can better adapt to the ever-changing world of manufacturing and thus gain a competitive advantage over other businesses within their industry.

Some of the major challenges faced by the metal casting process include high tooling costs, long lead times, and limited design flexibility, all of which can negatively affect the monetary budget and time constraints of businesses that rely on cast metal components.

To offset high tooling costs, a high production volume is often required. And that’s where 3D printing comes in.

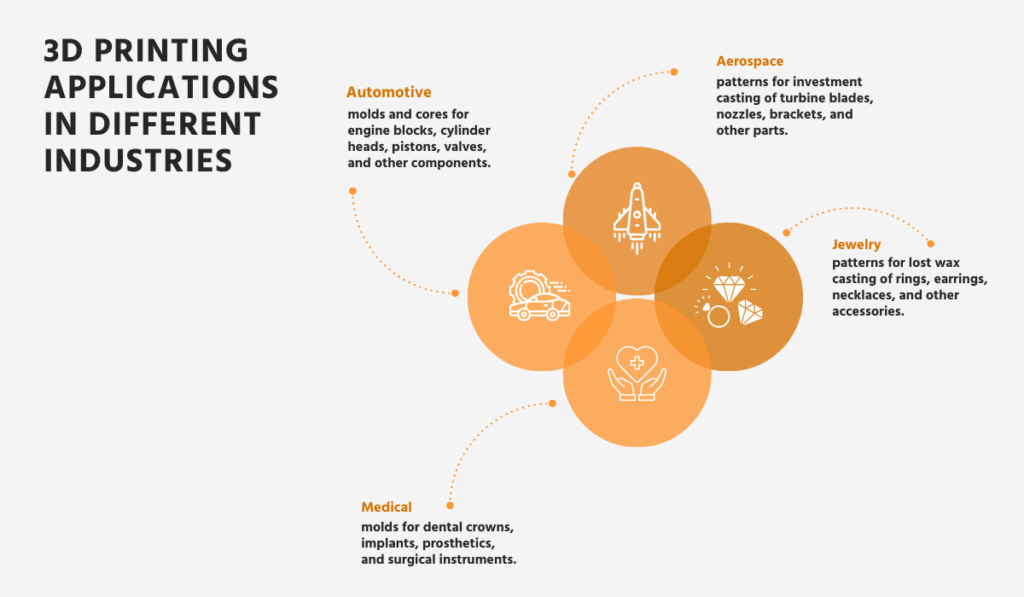

3D printing can be used to create molds, cores, and patterns for metal casting, as well as provide several other benefits that traditional methods can not. For example:

| Reduced tooling costs and lead times | 3D printing eliminates the need for expensive and time-consuming machining or CNC milling of molds, cores, and patterns. Instead, these parts are printed directly from a digital file, saving both money and time. |

| Increased design freedom and complexity | 3D printing allows for more complex and intricate geometries that are difficult or impossible to achieve with conventional methods. Utilizing 3D printing enables more creative and functional designs, as well as more customization and personalization of metal parts. |

| Improved accuracy and quality | 3D printing can produce molds, cores, and patterns with high dimensional accuracy and surface finish, resulting in better casting quality and less post-processing requirements. |

| Enhanced sustainability and efficiency | 3D printing reduces material waste and energy consumption by using only the necessary amount of material and minimizing scrap. It also enables the use of recyclable or biodegradable materials (e.g. PLA and sand). |

The 3D printing for metal casting trend is gaining momentum in several industries that rely on custom metal parts for their applications.

For example:

The above examples are just some of the most prominent examples of how 3D printing is revolutionizing metal casting and creating new opportunities for innovation and growth within modern-day manufacturing.

In recent years, metal manufacturers have been using more alternative materials to replace steel in hopes of improving the performance and cost-effectiveness of the casting process.

That’s because different metals have different properties that make them more suitable for specific applications.

Some examples of alternative materials that are displacing steel in metal casting are:

Aluminum is a lightweight, corrosion-resistant, and recyclable metal that can be cast into complex shapes and thin walls and alloyed with other metals to improve their mechanical properties.

This metal is widely used in automotive, aerospace, marine, and consumer industries for making engine blocks, cylinder heads, wheels, frames, housings, and other components.

Magnesium is another lightweight metal that can be cast into intricate shapes and thin sections. It has a low density and offers a good degree of stiffness and vibration damping.

It is mainly used in automotive, electronics, medical, and defense industries for making steering wheels, instrument panels, laptop cases, camera bodies, and missile components.

Copper is ductile, malleable, and conductive, which allows it to be cast into various forms and sizes.

This alternative metal has excellent thermal and electrical conductivity and corrosion and oxidation resistance, which is why it is used in electrical, plumbing, heating, and cooling industries for making wires, pipes, fittings, coils, and heat exchangers.

Plastic is a synthetic material that like metal can be molded or extruded into different shapes and sizes. Plastic has many advantages over metal including lower cost, lighter weight, higher flexibility, and more design freedom.

This synthetic material is widely used in various industries such as packaging, medical, consumer, and construction for making bottles, containers, syringes, toys, furniture, and insulation.

FRP is a composite material that consists of a polymer matrix reinforced with fibers (e.g. glass, carbon, and aramid). This material has high strength, stiffness, and fatigue resistance, allowing it to withstand harsh environments and chemical attacks.

FRP can be used as an alternative to steel in building and infrastructure industries for making beams, columns, panels, bridges, and pipes.

Using the above materials instead of steel to produce metal-cast parts has produced several benefits for manufacturers and industries that use metal-cast components for their applications.

The following are three examples of such benefits:

| Lower energy consumption | Alternative materials such as aluminum, magnesium, and plastic require less energy than casting steel as they have lower melting points and specific heat capacities – properties that reduce fuel consumption and greenhouse gas emissions. |

| Higher productivity | Materials such as plastic and FRP tend to offer higher productivity levels than casting steel due to their shorter cycle times and lower scrap rates. |

| New technologies | Using plastic and FRP sometimes requires new technologies such as injection molding, extrusion molding, and pultrusion to produce the desired shapes and sizes. These technologies can offer a cost, time, and quality advantage over more conventional metal casting methods in terms of equipment, tooling, and quality control. |

The current trend of using alternative materials instead of steel in metal casting can help lower costs and improve performance (e.g. mechanical, thermal, and electrical properties), which leads to a positive effect on real-world applications and overall customer satisfaction.

High energy consumption, environmental pollution, quality defects, and labor shortage are some of the main problems metal manufacturers face when engaging in metal casting.

So, to overcome these challenges and improve the efficiency, quality, and sustainability of the metal casting process, many foundries have started embracing smart technologies that leverage data, automation, and artificial intelligence.

Some of the smart technologies that are now being used in metal casting include:

This technology uses a digital model to print sand molds and cores layer by layer, eliminating the need for patterns and tooling.

This technology uses algorithms to learn from data and make predictions and decisions on various aspects of metal casting (e.g. process optimization, defect detection, quality control, predictive maintenance, and intelligent design).

Robotics and automation can be used to enhance the productivity, safety, and consistency of metal casting operations.

For example, this technology can optimize and automate the material handling, mold making, pouring, cleaning, and inspection steps of metal casting.

AR and VR technology can be used for training, simulation, visualization, and collaboration in metal casting (e.g. showing instructions, displaying data, testing scenarios, and sharing information).

The use of smart technologies in metal casting has been shown to enhance the process in several ways.

For example:

All of the above benefits brought about by smart technologies help manufacturers increase competitive advantage, meet customers’ demands, and reduce operational costs.

Many industries have also derived quite a few benefits from this trend.

For example, in the automotive industry, smart technologies help produce lighter, stronger, and more efficient components for engines, transmissions, chassis, and brakes.

Next, smart technologies help produce aircraft components that require intricate shapes with high precision and accuracy such as turbines, propellers, and wings.

Likewise, these technologies can assist in the production of customized implants with biocompatible materials that are suitable for joints, bones, and teeth.

By looking at the above benefits and applications, it can be seen that the use of smart technologies in casting is transforming the way metal cast parts are produced.

Since they enable real-time monitoring, control, and optimization of the casting process, they greatly assist in reducing defects, waste, and energy consumption, and therefore help businesses in a variety of industries meet the increasing demand for complex, customized, and high-performance metal parts.

The metal casting process generates a lot of waste, emissions, and energy consumption, impacting both the environment and human health.

To address these issues, metal manufacturers have made a focused attempt to increase environmental sustainability by implementing various strategies that help reduce their environmental footprint by improving the efficiency of the metal casting process.

Some examples of these strategies are:

By implementing the above strategies, metal casting companies not only help reduce environmental damage but also gain several other business advantages, which they can pass on to their customers.

These include:

Some of the industries will derive the most benefits through the current environmental sustainability trend in metal casting.

For instance, by using environmentally friendly castings, automotive manufacturers can reduce their fuel consumption, emissions, and noise levels, as well as improve the safety standards and durability of their products.

On the other hand construction companies benefit from using green castings. They improve their indoor air quality, energy efficiency, and water conservation, as well as reduce their maintenance costs.

Aerospace companies, on the other hand, can enhance their aerodynamics, performance, and reliability, as well as reduce their weight and fuel consumption, just by using sustainable castings.

As you can see, the environmental sustainability trend in metal casting is producing significant benefits for both the environment and the businesses that rely on it.

By adopting eco-friendly practices and innovations in regard to casting, metal manufacturers can create a positive impact on the world while also increasing the profitability and growth of their customers.

Metal casting is a dynamic and evolving industry that is constantly adapting to new challenges and opportunities.

The four trends that have been discussed in this article are prime examples of the current adaptations, which are transforming the way metal parts are designed, produced, and used.

While all of these new innovative strategies and technologies are exciting indeed, incorporating them into your metal parts project can be quite the challenge as it takes relatively large amounts of time, money, and know-how to do so.

That’s why we suggested seeking out an expert metal parts manufacturer who can help you implement these trends into your next project.